Radar versus lidar

All of the ACC systems available today are built around sensors that detect the vehicle ahead through the use of either radar or lidar (light detecting and ranging, the laser-based analog to radar). The choice of sensor presents classic design tradeoffs. Lidar is less expensive to produce and easier to package but performs poorly in rain and snow. The light beams are narrower than water droplets and snowflakes, pushing down the signal-to-noise ratio in bad weather. Which is precisely when you need it most, argues Tony Stewart, a project engineer at Fujitsu Ten Ltd., Plymouth, Mich., which is working on an advanced ACC using radar. Another problem is that accumulations of mud, dust, or snow on the car can block lidar beams.

At present, only one automaker, Lexus, uses a laser-based ACC system, in its LS430 luxury sedan. System engineers have acknowledged lidar’s shortcomings and taken steps to make the system unavailable in situations where the weather may limit its effectiveness. According to the LS430 owner’s manual, the system will automatically shut itself off if the windshield wipers are turned to a rapid setting, indicating heavy rain or snow; if something activates the anti-lock braking system (which helps the driver maintain steering control and reduces stopping distances during emergency braking situations); or if the vehicle skid control system detects the slipping of tires on turns that is common in wet weather.

Radar-based systems, on the other hand, can “see” at least 150 meters ahead in fog or rain heavy enough to cut the driver’s ability to see down to 10 meters or less. The choice of radar or lidar depends on the designers’ philosophy: proponents of the laser-based systems insist that a collision-warning system should not work far beyond what the driver can see. To do so, they say, would encourage people to drive too fast in conditions of poor visibility and lead to crashes when the collision-warning system failed to detect an obstacle. Conversely, proponents of radar-based systems argue that the driver needs the most help in conditions of poor visibility.

A typical automotive radar is roughly the size of two stacked paperback books—just 14 by 7 by 10 cm

Radar-based systems employ a variety of sensing and processing methods to determine the position and speed of the vehicle ahead. A fairly simple scheme (like the one used by Mercedes) switches rapidly among three beams by changing feed points along the antenna, creating a scanning effect inexpensively and with no moving parts. The beams are wide enough to ensure that each overlaps those adjacent, providing a combined 12-degree field of view. An advantage is that the wider beams permit the use of a smaller antenna.

More advanced and costlier sensing schemes rely on an antenna that is mechanically scanned and that emits a narrow beam. These systems scan between 64 and 128 points in the radar’s field of view, also typically 12 degrees, so that resolution is much higher than for a three-beam system. The beams are much narrower than in the three-beam models, however, so the antenna has to be larger. And the multiplicity of beams requires much more processing power to handle the streams of data that pour out as the radar scans across the multiple points of focus to determine the leading car’s position and speed.

Regardless of the scanning mechanism, the radars typically operate in the millimeter-wave region at 76-77 GHz. The automakers refused to alter the shape or construction of their vehicles to accommodate ACC, so designers had to build systems small enough to be mounted inside a car’s front grille. That stringent size requirement in turn demanded a compact antenna, which in turn forced the use of the high frequencies, antenna size being inversely related to frequency. At 76-77 GHz, frequencies are high enough to work with small antennas, yet not so high that the components are exotic and stupendously expensive. A typical automotive radar, produced by Delphi Delco Electronics Systems, of Kokomo, Ind., is roughly the size of two stacked paperback books–just 14 by 7 by 10 cm.

Engineers considered frequencies even higher than 76 GHz, such as 94 and 125 GHz, but the components required are prohibitively expensive at the moment. All the same, engineers have not given up on higher frequencies, which would let them shrink the antennas, whose size dominates the overall system size. Smaller units would give designers more flexibility in the location of the devices. Instead of being centered behind the car’s front grill, which is where they must go today, they could be mounted on a car’s rear-view or side mirrors or near a headlight.

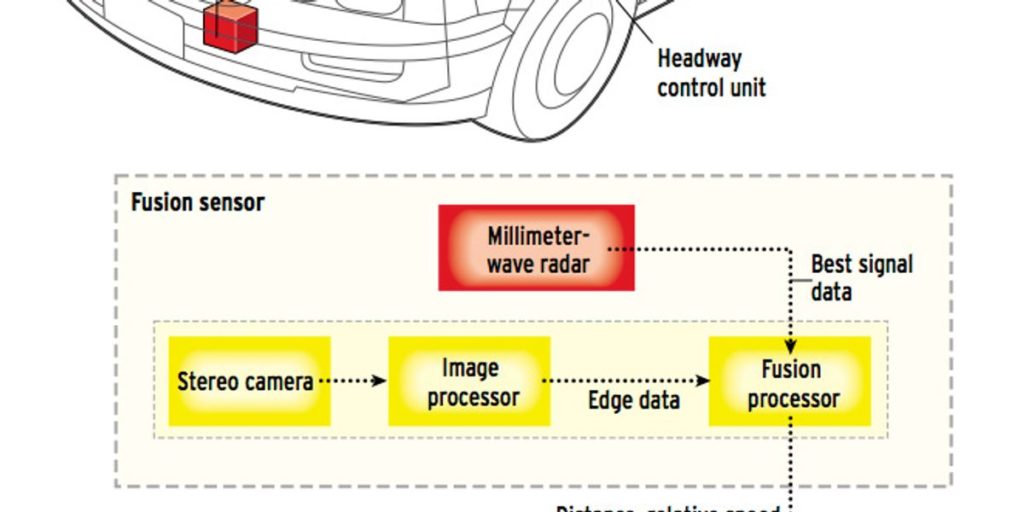

Such leading-edge technologies as monolithic microwave integrated circuits (MMICs), initially developed for military and communications applications, also contribute mightily to compactness. Engineers put an entire radar system on a handful of these circuits. The chip set includes a microprocessor that communicates with a digital signal processor and the radar’s scanning mechanism. It feeds a separate control computer, which decides whether to engage the throttle or brakes.

Automakers are now striving to integrate all of these functions into a single chip, said Osman Altan, an engineer at General Motors’ Research and Development Center, in Warren, Mich. Such an advance would make the systems cheaper to produce and less vulnerable to interference.

Yet another enabling technology is flip-chip packaging, an advanced and compact method of making electrical connections to an IC. Besides permitting more accurate placement of more numerous chip leads, it lowers production costs and enhances ruggedness and reliability.