Aluminum busbars are critical components in electrical distribution systems, serving as conductive pathways for distributing electricity. These busbars, made from aluminum or aluminum alloys, offer numerous advantages over traditional copper bus bars, including reduced weight and cost-effectiveness. Their use in various applications, such as bus ducts and power distribution networks, demonstrates the versatility and reliability of aluminum. Aluminum busbars use lightweight materials that can efficiently handle high current loads while minimizing thermal management issues. The extraction of aluminum from raw materials has led to a significant increase in its availability, making aluminum an attractive choice for a wide range of industrial and commercial applications.

| Application | Advantages | Typical Current Rating |

|---|---|---|

| Power Distribution | Lightweight, cost-effective | Up to 5000 A |

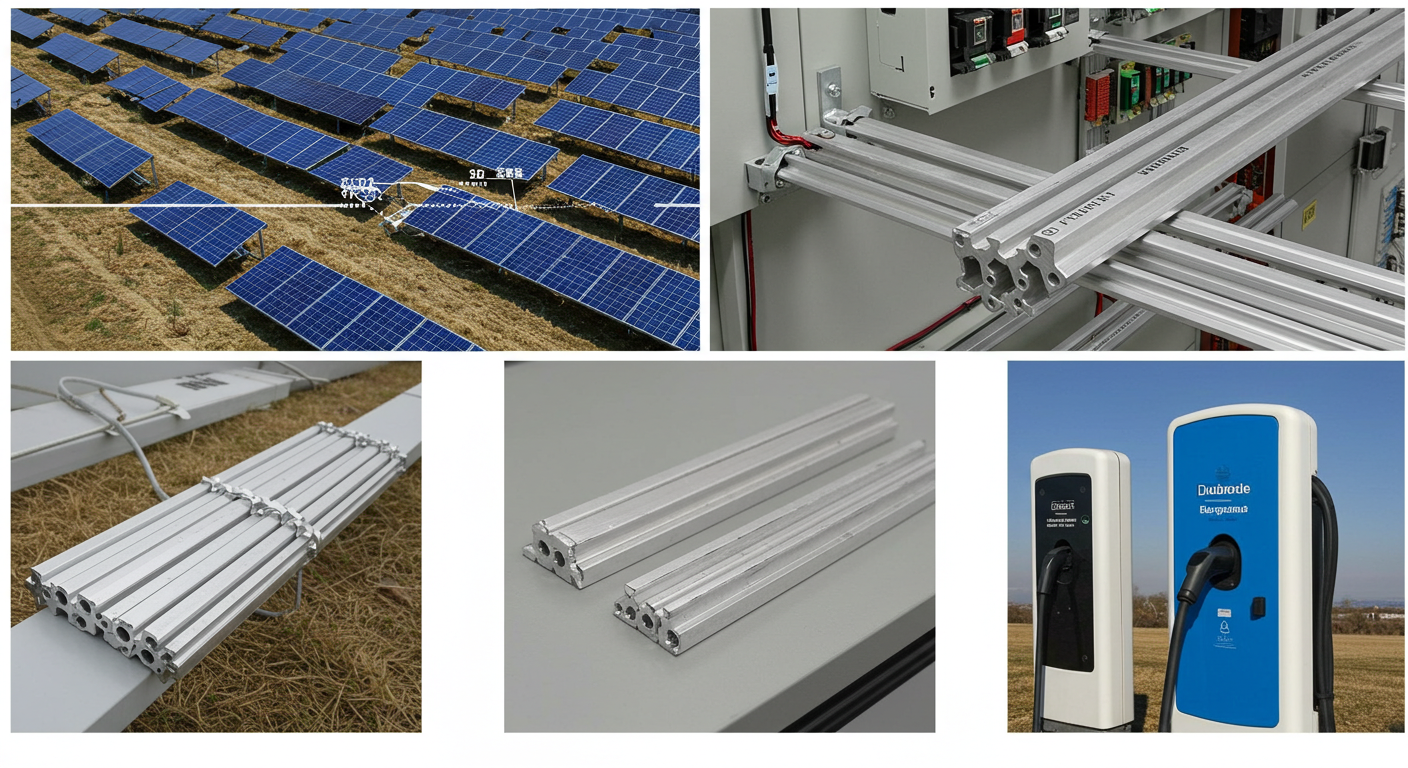

| Solar Energy Systems | Corrosion-resistant, easy installation | Up to 3000 A |

| Industrial Automation | High conductivity, reduced thermal loss | Up to 2000 A |

| Data Centers | Space-saving, reliable performance | Up to 4000 A |

Contents

- 1 Advantages of Using Aluminum Busbars

- 2 Applications of Aluminum Busbars

- 3 Key Characteristics of Aluminum Busbar Systems

- 4 Selecting the Right Busbar Material

- 5 Flexible Aluminum Busbars

- 6 Conclusion

- 7 FAQS

- 7.1 What are the advantages of using aluminum bus bars compared to other busbar materials?

- 7.2 How can the use of aluminum in busbars enhance the electrical performance of products such as aluminium busway or other busbar solutions?

- 7.3 How does the use of aluminum in busbar solutions differ from using other materials in terms of recyclability and electrical performance?

- 7.4 How can the use of aluminum in busbar solutions be beneficial for developing electrical products that are recyclable and efficient?

- 7.5 How does the use of aluminum in the construction of busbars affect the overall efficiency of electrical products?

- 7.6 How does the use of aluminum in busbar applications impact the efficiency of electrical products?

- 7.7 How does the integration of aluminum bus in electrical products impact their overall performance and efficiency?

- 7.8 How does the use of aluminum busbars contribute to the overall performance of electrical products?

- 7.9 How do aluminum busbars influence the design and functionality of electrical products?

- 7.10 How do aluminum busbars impact the efficiency and performance of electrical products?

Aluminum Busbars use | What are Busbars?

Busbars are conductive materials designed to distribute electrical power efficiently within various systems, often made from aluminum alloy due to its lightweight and conductive properties. The use of aluminum in busbars is prevalent because it provides a favorable balance of conductivity and weight, particularly in the form of cast aluminum or specialized aluminum alloys like 6061 aluminum and 6061-T6 aluminum. These materials are capable of handling high current loads and are utilized widely in busway systems, where aluminum wire serves as a key component.

Aluminum Busbars use extends to various industries, including transportation and renewable energy sectors, where aluminum recycling plays an important role in sustainability. The use of aluminum powder and aluminum conductors not only enhances performance but also supports eco-friendly practices. Selecting aluminum busbars ensures a reliable and efficient power distribution solution while benefiting from the inherent advantages of aluminum, such as resistance to corrosion and ease of fabrication.

Types of Busbars

Busbars can be classified based on their material composition and intended applications. Aluminum busbars use lightweight properties while offering excellent conductivity, making them suitable for various industries. Steel busbars provide robust support for heavy-duty applications, whereas copper-clad aluminum wire combines the benefits of both metals. These are often utilized in environments where strength and electrical performance are critical, such as in vehicles and aerospace applications.

Another classification involves the physical characteristics of busbars, such as flexible and rigid designs. Flexible aluminum busbars are ideal for dynamic settings like press brakes, where movement is frequent. Rigid options are typically found in fixed installations, providing durability and stability. Accessories like rubber insulators and soldering iron connections enhance the performance of these systems in electric vehicles and industrial machinery, emphasizing the diverse Aluminum Busbars use across various sectors.

Advantages of Using Aluminum Busbars

Aluminum Busbars use has gained popularity due to several advantageous properties that cater to modern needs in various infrastructures. Lightweight yet strong, these busbars enable easier handling and reduce the load on supporting structures. The machining of aluminum, paired with finishes like zinc coating, enhances its corrosion resistance, making it ideal for long-lasting applications. Techniques such as soldering and sanding help achieve optimal connections, while tap drill tools simplify installation processes. Flexible options in design allow for innovative configurations that can adapt to different power requirements. These characteristics contribute to the overall efficiency and durability of electrical systems, establishing Aluminum Busbars as a trusted choice in contemporary applications.

Lightweight Properties

Aluminum busbars offer significant weight advantages, making them ideal for various applications. Their lightweight properties mean that they are easier to handle during installation, reducing labor costs and time. For companies like Honda, incorporating aluminum busbars into their machines can enhance overall efficiency. The reduced weight also allows for simpler structural support, which is especially important in automotive and industrial settings that rely on multiple tools and components.

Using aluminum busbars is increasingly popular due to their favorable strength-to-weight ratio. An aluminum busbar system provides the necessary conductivity without the cumbersome nature of heavier materials. This is particularly beneficial for manufacturers looking to optimize their power distribution systems. The lightweight characteristic of aluminum busbars does not compromise their functionality, making them a smart choice for those involved in designing and operating complex machinery.

- Enhanced portability for easy transport and mobility within facilities

- Lower energy consumption during operation due to reduced overall load

- Increased flexibility in design and layout of electrical systems

- Improved thermal management due to efficient heat dissipation

- Greater corrosion resistance, ensuring longevity and reduced maintenance

- Easier compliance with building and safety regulations

- Cost-effective solutions by minimizing the need for extensive structural reinforcements

Cost-Effectiveness Compared to Copper Busbars

Aluminum Busbars use is increasingly favored in various applications due to their cost-effectiveness compared to traditional copper busbars. Solid aluminum busbars offer a lower weight alternative, reducing shipping and handling costs. The initial investment for high-quality aluminum busbars is often less than that of copper busbars, which can lead to significant savings for projects. Flexible aluminum busbars also provide the added advantage of ease of installation, making them a practical choice for many electrical systems.

The durability of aluminum busbar systems enhances their financial appeal over time. Series aluminium busbars exhibit strong resistance to corrosion, which minimizes maintenance costs and extends the lifespan of the system. As industries continuously seek ways to optimize budgets, the option of top-quality aluminum busbars makes sense for both large-scale and small-scale projects. With the various types available, including solid and flexible aluminum busbars, organizations can tailor their needs to fit both performance and budget considerations.

Applications of Aluminum Busbars

Aluminum Busbars are widely utilized across various industries due to their versatile properties and excellent performance. The lightweight design of aluminum busbars makes them easier to handle and install compared to copper busbars, while their flexibility is enhanced by options like flexible aluminum busbars, which adapt to different configurations in installations. The use of top-quality aluminum bus materials ensures reliable performance in demanding environments, including industrial settings and power distribution systems. Threaded aluminum bus designs simplify connections, facilitating effective busbar applications. Selecting the right busbar material is crucial for optimizing effectiveness and durability, making aluminum busways a practical choice for modern electrical systems and supporting efficient busbar manufacturing.

Industrial and Commercial Uses

Aluminum Busbars use has become increasingly popular in industrial and commercial settings due to their effective performance and versatility. Businesses often choose busbars over traditional copper busbars for a range of applications, including power distribution and electrical systems. The busbar construction of tinned busbars enhances conductivity and corrosion resistance, making them suitable for diverse environments. Notably, products like the electrical aluminum bus cater to various specifications, allowing industries to optimize their operations.

The flexibility of aluminum busbars also allows for innovative designs, such as thin busbars that save space without sacrificing performance. With an expanded busbar offering, companies can select the best materials for their specific needs. This is crucial in busbar production where efficiency and reliability are paramount. Many industries now opt for their own busbars tailored to unique applications, further emphasizing the widespread Aluminum Busbars use in modern electrical infrastructure.

Power Distribution Systems

Aluminum Busbars use is becoming increasingly significant in power distribution systems, particularly as a viable alternative to traditional copper busbars. These aluminum bars can be integrated into various setups, including horizontal-profiled busbars, which optimize space and efficiency. The adaptability of aluminum allows for longer busbar lengths, making it ideal for extensive electrical networks. Busbar mounts are crucial for securing these systems, ensuring stability while allowing for easy access during maintenance.

Traditional busbars often fall short in performance and cost-effectiveness compared to their aluminum counterparts. Applications involving mesh busbar designs enhance the distribution process, offering a lightweight solution without compromising conductivity. In any next busbar project, the choice of aluminum busbars can lead to significant advancements in durability and efficiency. By making the switch from copper bus bars, industries can benefit from improved thermal management and reduced operational costs.

| Feature | Aluminum Busbars | Copper Busbars |

|---|---|---|

| Weight | Lightweight | Heavier |

| Cost | Lower initial cost | Higher initial cost |

| Thermal Management | Improved efficiency | Standard efficiency |

| Flexibility | More adaptable for various designs | Less flexible |

| Maintenance | Easy access for maintenance | More complex access |

Key Characteristics of Aluminum Busbar Systems

Aluminum Busbars use hard aluminum bars, which provide excellent conductivity while being significantly lighter than alternatives. The versatility of aluminum bars allows for various configurations, such as profile busbars or phoenix busbars, accommodating different installation requirements. A notable characteristic of these systems is their robust bus bar surface, which can often be enhanced with finishes such as nickel-plated copper busbars for improved performance. Aluminum Busbars also feature predrilled/tapped copper busbars, facilitating easier connections and installations. The availability of flexible aluminum bars ensures adaptability in constrained spaces, making them ideal for applications where traditional rigid bus bars might not fit. Ultimately, the combination of these attributes makes aluminum busbars a reliable choice for effective power distribution systems.

Conductivity and Thermal Management

Aluminum Busbars use benefits greatly from aluminum’s excellent conductivity. The material’s ability to conduct electricity efficiently allows for reduced energy loss during transmission. This characteristic is particularly advantageous in systems with a solid aluminum bar configuration, where maximizing efficiency is crucial. Factors such as bus bar holes and the overall bus bar weight contribute to the effective performance of aluminum components. A well-designed system of wider or thinner bus bars can significantly impact conductivity, ensuring optimal energy distribution.

Thermal management is another essential aspect of aluminum busbars. High-quality aluminum maintains lower operating temperatures compared to other metals, enhancing reliability in various applications. The thermal performance of aluminum busbars differs from that of copper options, making them a preferred choice for many industries. The proper selection of the right bus bar can lead to improved heat dissipation, which is vital for preventing overheating in bus boards and electrical systems. Aluminum people in engineering and design fields often prioritize these attributes when choosing the most effective busbar solution.

Durability and Corrosion Resistance

Aluminum offers exceptional durability, making it an ideal material for busbars in various applications. With its lightweight properties, aluminum can effectively support diverse bus bar widths while maintaining structural integrity over time. The strength of aluminum components enhances reliability in demanding environments. This resilience is further bolstered by proper aluminum fasteners, ensuring that connections remain secure even under stress, leading to efficient bus bar distribution.

Corrosion resistance is a critical factor for long-lasting aluminum busbars. Aluminum forms a protective oxide layer that prevents deterioration, ensuring the aluminum core maintains optimal performance. The implementation of a well-thought-out bus bar plan ensures that enough aluminum is used to withstand environmental factors. Clean aluminum surfaces enhance the effectiveness of this protective layer, contributing to the longevity of the busbar system. The versatility of aluminum varies based on thickness, allowing for tailored solutions suited to specific operational demands.

Selecting the Right Busbar Material

Choosing the right busbar material involves carefully considering factors unique to each application. Aluminum Busbars use is becoming increasingly popular due to the lightweight properties and excellent conductivity of raw aluminum, which serves as a compelling alternative to its copper counterpart. The selection process also entails evaluating the aluminum profile and understanding how bus bar connections can impact overall efficiency. For instance, trf bus bars made from aluminum core materials can minimize weight without sacrificing strength. Industries often prefer zinc/aluminum combinations to enhance corrosion resistance, while various aluminum forms and aluminum threads provide flexibility for customized installations. Formed aluminum solutions are particularly advantageous for creating complex busbar systems.

Comparing Aluminum and Copper Busbars

Aluminum Busbars use offers numerous advantages over traditional copper options. The lightweight nature of aluminum, combined with its electrical conductivity, makes it a popular choice for busway systems. Products like cast aluminum lugs and aluminum conductors provide an efficient means of power distribution. Aluminum fabrication delivers custom solutions that meet specific installation needs, with options such as aluminum rectangles capable of handling various electrical loads efficiently, ensuring that bus bar solutions are optimized for performance.

The recyclability of aluminum is another significant benefit. Unlike copper, which has a limited availability and higher costs, recyclable aluminum presents an eco-friendly alternative for bus bars.rex coil applications. Choosing electrical grade aluminum for busway systems allows for enhanced durability and reduced installation complexity. As industries increasingly seek sustainable solutions, aluminum’s versatility in fabrication and functionality will continue to drive its popularity in various electrical applications.

Factors Influencing Busbar Material Choice

Selecting the right busbar material often hinges on specific project requirements. Aluminum Busbars use high-strength aluminium alloys that offer both lightweight characteristics and considerable strength. Ductile aluminum alloy provides a flexible option that can withstand heavy loads without compromising performance. The consideration of pure aluminum rates can significantly influence the budget. For instance, using narrow bars results in reduced material costs, while opting for thicker bars may be necessary for applications demanding enhanced conductivity.

Transportation costs also play a crucial role in decision-making. Smaller, lighter aluminum busbars often fulfill project needs without incurring high shipping fees. In more robust applications, large stainless steel configurations may be preferable, particularly when paired with stainless steel nuts for durability. Zinc/aluminum powder coatings can enhance corrosion resistance, making aluminum busbars suitable for various environments. The right balance of strength, weight, and cost will determine the ideal busbar material for any application, emphasizing the importance of Aluminum Busbars use.

Flexible Aluminum Busbars

Flexible designs in aluminum busbars provide versatility and ease of installation in various applications. These aluminum busbars use a range of configurations, allowing for narrow or thicker bar options tailored to specific requirements. The lightweight nature of aluminum combined with its steel-like strength makes it an ideal choice for high loads in demanding environments. Various industries, including automotive applications, benefit from the adaptability of these bars, enabling seamless integration with panels and equipment. Fastening systems using stainless steel fasteners enhance the structural integrity of the connections, ensuring reliable performance in challenging conditions while also offering advantages over traditional copper bars.

- Enhanced flexibility allows for easier installation in tight spaces.

- Corrosion resistance ensures longevity and reliability in diverse environments.

- Lightweight design reduces overall project weight, improving handling and transport.

- Energy-efficient properties help in reducing overall system power losses.

- Customizable configurations support a wide range of electrical setups.

- Compatible with various fastening systems, ensuring robust connections.

- Cost-effective alternative to traditional copper busbars while maintaining performance.

Benefits of Flexible Aluminum Busbar Options

Flexible aluminum busbars are designed to optimize Aluminum Busbars use in various applications. The usage of a6063 bars allows these busbars to maintain mechanical strength while providing significant flexibility. The lightweight nature of aluminum minimizes the load on support structures compared to traditional copper bars. Their adaptability ensures they can fit into tight spaces without compromising electrical performance, making them a preferred choice in sectors like aerospace industries.

The construction of flexible aluminum busbars often involves a flat bar design that enhances their surface plane, providing improved contact with terminals. Unlike cheap iron alternatives, these aluminum options resist corrosion and maintain conductivity over time. This performance, combined with their flexibility, makes them ideal for dynamic environments where equipment may shift or require repositioning, ensuring efficient power distribution without risking failure.

Use Cases for Flexible Aluminium Busbars

Flexible aluminum busbars are designed for a range of applications that require efficient electrical conduction in tight spaces. These busbars can easily be manipulated to fit various configurations. The same tool used for installation, often a not-fancy soldering iron, can simplify the jointing process. Straps and stainless components ensure secure connections, mitigating unwanted rotation that can occur during operation.

In industrial settings, flexible aluminum busbars use allow for dynamic routing of electrical currents without compromising performance. Their adaptability makes them ideal for environments where traditional rigid busbars would struggle. This versatility increases their effectiveness in power distribution systems, providing reliable connections while accommodating changes in layout and equipment. The use of specialized tools further enhances installation efficiency, making them a preferred choice in modern electrical systems.

Conclusion

Aluminum Busbars use has become increasingly important in various electrical applications due to their lightweight properties and cost-effectiveness. High-quality aluminum busbars outperform traditional materials in many scenarios, making solid aluminum busbars a preferred choice. The design and functionality of aluminum busbar systems, especially flexible aluminum busbars, cater to the evolving needs of the industry. Top-quality aluminum busbars ensure efficient power distribution, while the reliability of solid aluminum busbars contributes to their widespread adoption. Series aluminum busbars meet the demands of both industrial and commercial environments, solidifying their role in modern electrical infrastructure. Effective aluminum busbar installation is crucial for maximizing performance and ensuring durability, especially in challenging conditions where corrosion resistance is necessary.

FAQS

What are the advantages of using aluminum bus bars compared to other busbar materials?

Aluminum bus bars offer several advantages over other busbar materials, including their lightweight nature, which allows for easier handling and installation. They also have excellent conductivity, making them suitable for applications that require aluminum conductor efficiency. Additionally, aluminum bus bars are often more cost-effective due to the lower material cost associated with aluminum extraction. Various aluminum bar configurations, such as flexible aluminium busbar designs, can be tailored to meet specific needs, whether for electrical aluminum busway systems or for metal-frame construction applications.

How can the use of aluminum in busbars enhance the electrical performance of products such as aluminium busway or other busbar solutions?

The use of aluminum in busbars can significantly enhance the electrical performance of products. High-quality aluminum serves as a highly efficient aluminium conductor, making it ideal for applications requiring long busbar lengths or multiple bus bar entries. Additionally, aluminum means better thermal management, which can be crucial in systems that dissipate gas or heat. Moreover, aluminium profiles can be designed to have varying widths—enabling the choice between wider/thinner bus bars based on specific needs or configurations. Importantly, aluminum is also a recyclable material, adding an eco-friendly aspect to its use in busbars, further solidifying its role as the next busbar application in modern electrical systems.

How does the use of aluminum in busbar solutions differ from using other materials in terms of recyclability and electrical performance?

The use of aluminum in busbars—aluminum offers several advantages over other materials. Firstly, aluminum is recyclable aluminum, making it an environmentally friendly choice for bus bar solutions. Furthermore, electrical aluminum bus products provide high quality aluminum conductivity, which enhances the overall electrical performance. Unlike traditional metal chunks, aluminum differs in terms of weight and adaptability, allowing for narrow/thicker bar configurations. This makes aluminum ideal for various applications, including those utilizing aluminium core components or aluminium busway systems.

How can the use of aluminum in busbar solutions be beneficial for developing electrical products that are recyclable and efficient?

The use of aluminum in busbar solutions can significantly enhance the performance of electrical products. Materials like electrical aluminum bus are lightweight and have excellent conductivity, making them ideal for various applications. Additionally, recyclable aluminium not only promotes sustainability but also ensures that bus bar solution.rex can be repurposed at the end of their life cycle. Moreover, using aluminum helps in reducing the overall weight of the products, contributing to easier installation and versatility in design, whether for a fence or for complex electrical systems that demand efficient push metal connections.

How does the use of aluminum in the construction of busbars affect the overall efficiency of electrical products?

The use of aluminum bus in busbar solutions can significantly enhance the efficiency of electrical products. Aluminum bus has a high conductivity, which contributes to minimizing energy loss, making it an ideal choice for various electrical applications. Additionally, utilizing aluminum bus helps in the lightweight construction of these products, further improving their performance and reliability in electrical systems.

How does the use of aluminum in busbar applications impact the efficiency of electrical products?

The use of aluminum busbar helps improve the efficiency of electrical products by enhancing conductivity and reducing weight, making electrical aluminum bus configurations more effective. Additionally, aluminum busbar solutions contribute to the overall performance and lifespan of electrical products.

How does the integration of aluminum bus in electrical products impact their overall performance and efficiency?

The use aluminum bus in electrical products significantly enhances efficiency and performance. Products like aluminum busbars contribute to better conductivity and reduced energy loss, making them ideal for various busbar end applications. Additionally, incorporating aluminum bus in electrical solutions aligns with sustainable practices, ensuring that these products can be efficiently utilized in modern electrical systems.

How does the use of aluminum busbars contribute to the overall performance of electrical products?

The incorporation of aluminum busbars in electrical products enhances their performance by providing excellent conductivity, reducing weight, and ensuring efficient power distribution. These factors contribute to the efficiency and reliability of electrical products using aluminum busbars.

How do aluminum busbars influence the design and functionality of electrical products?

Aluminum busbars play a significant role in the design and functionality of various electrical products. The integration of aluminum bus in electrical products is known to enhance their overall performance due to the excellent conductivity and lightweight properties of aluminum, making them more efficient and reliable in electrical applications.

How do aluminum busbars impact the efficiency and performance of electrical products?

Aluminum busbars play a crucial role in enhancing the overall efficiency and performance of electrical products. By utilizing aluminum, manufacturers can achieve lower electrical resistance, which allows for better current flow and decreases energy losses. Additionally, aluminum busbars are lightweight yet strong, making them ideal for a variety of electrical applications. This combination of properties contributes significantly to the effectiveness and reliability of electrical products.