Researchers have demonstrated the integration of individual elements that make up filters onto a single electronic component. This could significantly reduce the amount of space taken up on a computer chip.

Electronic filters are essential to the inner workings of smartphones and other wireless devices. They eliminate or enhance specific input signals to achieve the desired output signals. Although essential, such filters take up space on the chips that researchers are on a constant quest to make smaller.

To address this issue, US researchers at the University of Illinois, Urbana-Champaign, have ditched the conventional 2D on-chip lumped or distributed filter network design – composed of separate inductors and capacitors – for a single space-saving 3D rolled membrane that contains both independently designed elements.

“With the success that our team has had on rolled inductors and capacitors, it makes sense to take advantage of the 2D to 3D self-assembly nature of this fabrication process to integrate these different components onto a single self-rolling and space-saving device,” said Xiuling Li, electrical and computer engineering professor at the university.

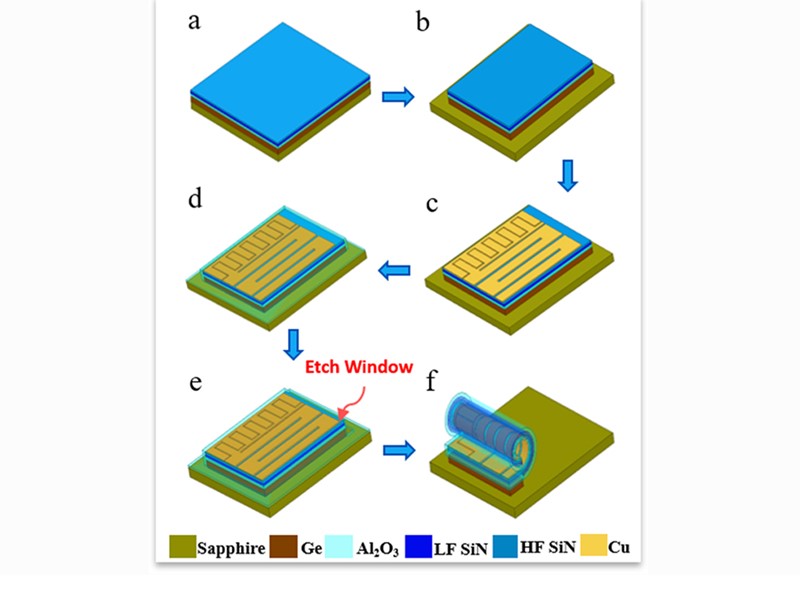

As part of the study, the researchers used a specialised etching and lithography process to pattern 2D circuitry onto very thin membranes. In the circuit, they joined the capacitors and inductors together and with ground or signal lines, all in a single plane. The researchers said this multilayer membrane can then be rolled into a thin tube and placed onto a chip.

The device-fabrication process includes the deposition of metals by electron-beam evaporation and lithography to define the metal pattern and etching process. The final etching step then triggers the self-rolling process of the stacked membrane.

Image credit: Graphic courtesy Xiuling Li

“The patterns, or masks, we use to form the circuitry on the 2D membrane layers can be tuned to achieve whatever kind of electrical interactions we need for a particular device,” said graduate student Mark Kraman. “Experimenting with different filter designs is relatively simple using this technique because we only need to modify that mask structure when we want to make changes.”

The team tested the performance of the rolled components and found that under the current design, the filters were suitable for applications in the 1-10 gigahertz frequency range, the researchers said. While the designs are targeted for use in radio frequency communications systems, the team said that other frequencies, including those in the megahertz range, are also possible based on their ability to achieve high-power inductors in past research.

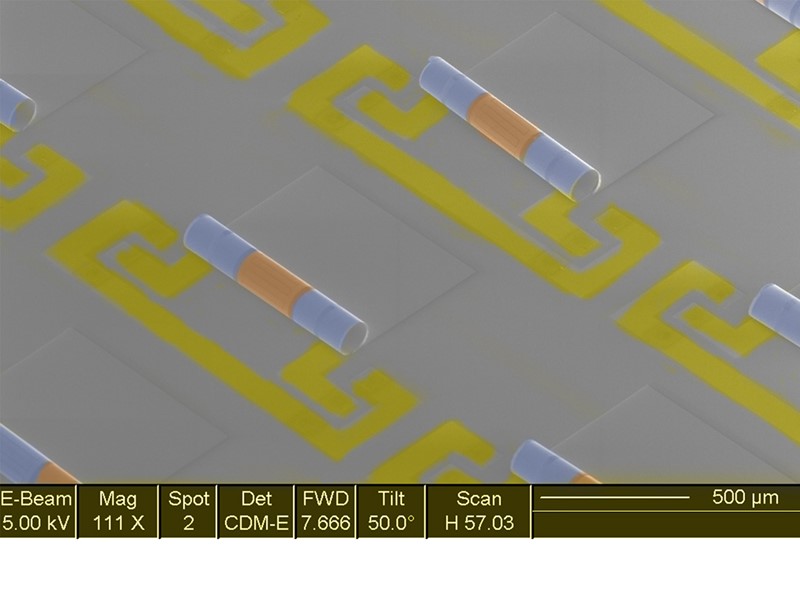

Electron microscope image of an array of new chip components that integrate the inductors, blue, and capacitors, yellow, needed to make the electronic signal filters in phones and other wireless devices.

Image credit: Xiuling Li

“We worked with several simple filter designs, but theoretically we can make any filter network combination using the same process steps,” said Mike Yang, another graduate student leading the study. “We took what was already out there to provide a new, easier platform to lump these components together closer than ever.”

Li added: “Our way of integrating inductors and capacitors monolithically could bring passive electronic circuit integration to a whole new level. There is practically no limit to the complexity or configuration of circuits that can be made in this manner, all with one mask set.”

Sign up to the E&T News e-mail to get great stories like this delivered to your inbox every day.