There were few bright spots in the pandemic summer of 2020. One of the most dazzling was the flight of U.S. astronauts to the International Space Station and their safe return to Earth aboard a commercial spacecraft from SpaceX. This demonstration was significant for many reasons, one of which was that it suggested a future in which NASA, freed from the demands of getting people to low Earth orbit, could aim much farther. Perhaps as far as Venus.

Excitement over a possible mission to Venus was stoked by the (now somewhat disputed) discovery of phosphine gas—a possible sign of microbial life—in that planet’s atmosphere. But the second planet from the sun has such an extreme environment that the longest-lasting lander, the Soviet Venera 13, was able to send data for only 2 hours and 7 minutes. The average surface temperature on Venus is 464 °C, the atmosphere is dense with highly corrosive droplets of sulfuric acid, and the atmospheric pressure at the surface is about 90 times that of Earth. Yet scientists think of Venus as our home world’s twin.

The size and mass of these two planets are very close, of course. And evidence points to similar early days: For as long as 3 billion years, Venus may have had massive oceans just like we do here on Earth, and therefore, perhaps, there was life. What cataclysmic events led to Venus’s loss of water? Planetary scientists would love to know, because it might inform our own fate as the climate changes.

To solve this and Venus’s other riddles, we’ll need several very capable robotic landers. But can we build machines—complete with instrumentation, communications, controllability, and mobility—that can survive such a hostile environment not just for hours but for months to years?

We can. Materials technology has advanced enough since the 1960s, when the former Soviet Union began launching its Venera series of landers to Venus, to ensure that the outer hull and mechanics of a future lander will be able to last for months. But what about those tender electronics? Today’s silicon-based systems would not last a day under Venus conditions. (We mean an Earth day, of course. A Venusian day is 243 Earth days.) Even adding active cooling systems might not give them more than an extra 24 hours.

The answer is a semiconductor that combines two plentiful elements, carbon and silicon, in a 1:1 ratio—silicon carbide. SiC can withstand extremely high temperatures and still work just fine. Scientists at the NASA Glenn Research Center have already operated SiC circuits for more than a year at 500 °C, demonstrating not only that they can take the heat but can do so over the kinds of lifetimes a Venus lander will need.

Silicon carbide is already making its mark in power electronics for solar inverters, electric-vehicle motor-drive electronics, and advanced smart-grid switch gear. But creating SiC circuits that can control a rover on the hellscape of Venus and send data from there to Earth will test this material to its limits. If it succeeds, we’ll get more than just a mobile outpost in one of the least hospitable spots in the solar system. We’ll also get insight into how to move wireless sensors into places on Earth that they’ve never gone before—on the blades of jet engines and natural-gas turbines, on the heads of deep oil-well drills, and inside a host of high-temperature, high-pressure industrial fabrication processes. The ability to locate electronics in these places has a meaningful chance of lowering the operating and maintenance costs of equipment while improving the performance and safety of both instruments and people in industrial settings.

In fact, our team, with members at KTH Royal Institute of Technology, in Stockholm, and at the University of Arkansas, in Fayetteville, believe silicon carbide circuits can take us there and beyond, to applications we have not yet imagined.

Silicon Carbide is not a new material by any means. Large-scale production is credited to Edward Goodrich Acheson in 1895. The American chemist was attempting to create artificial diamonds when his experiments produced crystals of SiC. The compound was first successfully used as an electronic material in 1906, when Henry Harrison Chase Dunwoody invented the SiC radio detector. To this day it is regarded as the first commercial semiconductor device.

However, large SiC crystals are notoriously difficult to manufacture in repeatable fashion, and it wasn’t until the late 1990s that engineers invented equipment that enabled the growth of crystals good enough to use to fabricate power transistors. These initial silicon carbide wafers were just 30 millimeters across, but the industry has slowly progressed to 50-, 75-, 100-, 150- and now 200-mm wafer diameters, making the devices more economical. Research and progress has steadily increased over the past 20 years to the point that SiC power semiconductor devices can now be purchased commercially.

Silicon carbide boasts some very attractive properties as a semiconducting material. The first of these is a critical electric-field strength almost 10 times that of silicon. That property is basically the point at which a material breaks down and begins conducting electricity uncontrollably, sometimes with explosive results. So if you’ve got a silicon device and a silicon carbide device of the same scale, the one made of silicon carbide can handle 10 times as much voltage. Alternatively, if the two transistors were built to handle the same voltage, the silicon carbide device could be physically much smaller. That size difference translates to a power-consumption advantage. For the same “breakdown voltage” (1,200 volts, say), a SiC transistor has 1/200th to 1/400th the “on” resistance of a silicon transistor, and therefore lower power losses. This smaller size also allows for higher switching frequency in a power converter, which would mean smaller, lighter, less costly capacitors and inductors.

Silicon carbide’s second amazing attribute is thermal conductivity: As the SiC heats up due to electrical conduction, the heat can be rapidly removed, prolonging the lifetime of a device. In fact, among wide-bandgap semiconductors, the thermal conductivity of SiC is second only to that of diamond. This property lets you connect a high-power silicon carbide transistor to the same size heat sink you’d use on a much lower-power silicon component and still get a fully functional, long-lasting device.

From the standpoint of scientists hoping to explore other planets, the radio is arguably the most vital system.

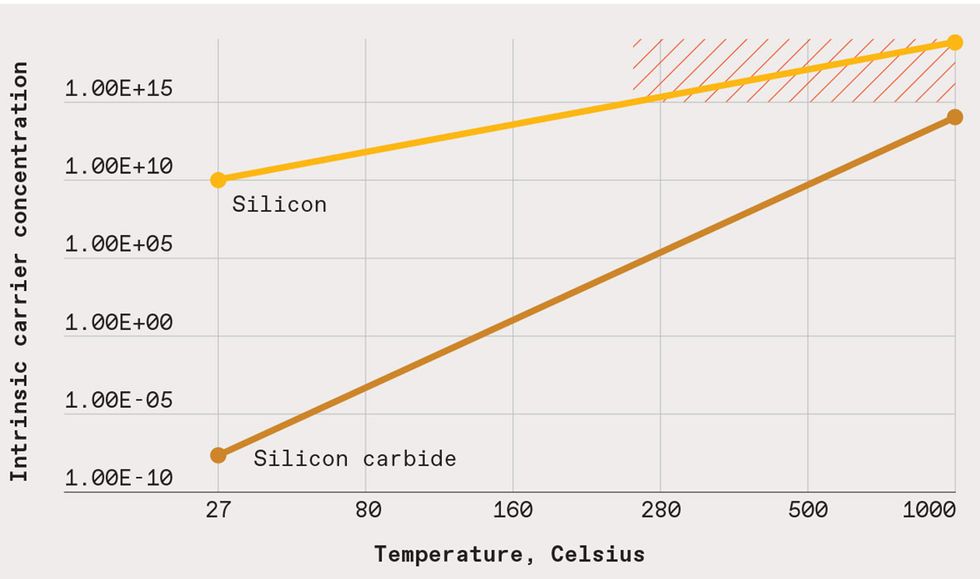

A third property, the most relevant to operating on Venus, is SiC’s very low intrinsic concentration of charge carriers at room temperature. The intrinsic carrier concentration corresponds to how many charge carriers heat makes available to conduct electricity. (Doping a semiconductor with atoms of another element can increase the available charge carriers. But the intrinsic concentration is what’s there without doping.) You might think that a low value here, particularly one that’s lower than silicon’s, would be a bad thing. But that’s not the case if we want to operate at high temperatures.

Here’s why. The reason silicon stops working as a semiconductor when temperatures climb is not because it melts, or burns, or anything that dramatic. Instead, the transistors start to become flooded with thermally generated charge carriers. Heat gives some electrons enough energy to boil up out of the valence band, where they are bound to atoms, and into the conduction band, leaving behind positively charged holes. The separated electrons and holes can now contribute to conduction. At moderate temperatures, say 250 to 300 °C for silicon, this just makes transistors leak current and become noisy. But at higher temperatures, the intrinsic carrier concentration exceeds whatever contribution doping has provided, and you can no longer turn the transistors off—they become like switches stuck in the “on” position.

By contrast, SiC, with its wider bandgap and fewer intrinsic charge carriers, has far more temperature headroom before the onset of “transistor flooding” occurs, enabling it to continue to switch well above 800 °C.

Collectively, these properties allow SiC to function at a higher voltage, power, and temperature than silicon can. And, even for temperatures where silicon is able to function, SiC often outperforms it because the devices can be switched at higher frequencies with lower losses. Put it all together and you have devices that are more efficient and rugged, and circuits and systems, that are smaller, lighter weight, and capable of surviving in the Venusian environment.

While a future Venus lander will need its share of high-voltage power transistors, most of its circuits—in processors, sensors, and radios—need to be of the low-voltage variety. Those are much less developed in silicon carbide than in silicon, but thanks to a problem of packaging, we’ve made a start.

As discrete silicon carbide power devices found commercial usage, engineers recognized the need to reduce electrical parasitics—unwanted resistance, inductance, and capacitance, which wastes power. One way is to better integrate, through advanced packaging, the control, drive, and protection circuits with the power devices. In silicon power electronics, these circuits are situated on printed circuit boards (PCBs). But at the higher frequencies SiC power transistors can achieve, the PCB’s parasitics may be too great, leading to excessive noise. Packaging or even integrating these circuits with the power devices would remove the noise. But the latter option would mean making these circuits out of silicon carbide.

At room temperature, silicon carbide is not a natural choice for low-voltage microelectronics for several reasons. Perhaps the most important is that the voltage can’t really be all that low, so neither is power consumption. Silicon’s small bandgap means you can power microelectronics with as little as 1 V. But silicon carbide’s bandgap is nearly three times as large. Therefore, the minimum voltage needed to push current through a transistor—the threshold voltage—is also greater. We generally use 15 V to supply our “low-voltage” SiC microelectronics.

Investigators around the world have attempted low-voltage microelectronics in SiC for more than 20 years, at first with limited success. During the past 10 years, however, researchers at our universities as well as at Cree, Fraunhofe Institute for Integrated Systems and Device Technology, Purdue University, NASA Glenn, University of Maryland, and Raytheon UK have made some breakthroughs.

As temperature increases, so does a semiconductor’s intrinsic carrier concentration—the number of electrons with enough energy to contribute to conduction. After a certain concentration is reached, a transistor is effectively flooded with charge carriers and will not turn off. This happens for most silicon devices at around 250 °C, but silicon carbide devices can still switch at 1,000 °C.

Illustration: Erik Vrielink

One of the first key microelectronic circuits built by the Arkansas team was a gate driver, which directly controls a power transistor through its input terminal, or gate. We’ve now completed several versions of the circuit—which can be packaged with (or even on top of) the power device—and tested them at Venus-like temperatures. This circuit, as well as later versions, enabled very high fidelity control of the power devices, maximizing efficiency while minimizing electromagnetic interference. The biggest challenge was to achieve a design that could adapt to changing conditions and even account for the effects of aging, which are bound to occur in the harsh conditions on Venus.

Gate drivers are important, but from the standpoint of scientists hoping to explore other planets, the radio is arguably the most vital system. After all, there’s no point in sending a package of scientific instruments to another planet if you can’t get the data back to Earth.

Compact, rugged radio systems may be even more crucial to future planetary missions, because they could carry data within the rover itself, replacing some of the thousands of point-to-point wires in these machines. Eliminating wires in favor of wireless command and control saves substantial mass, a vital commodity on a 40-million-kilometer trip.

So much of our most recent effort has been the design and testing of the components of a silicon carbide–based interplanetary radio transceiver. Silicon carbide would be nobody’s first choice for, say, a 5G radio operating on Earth. For one thing, at room temperature its charge-carrier mobility—part of what sets an upper limit to the frequencies a semiconductor can amplify—is lower than silicon’s. But at Venus surface temperatures, silicon no longer functions at all, so it makes sense to try to adapt silicon carbide to the task.

We’ve designed, built, and tested some 40 different circuits for 500°C conditions.

With regard to radio frequencies, silicon carbide does have one thing in its favor. The sparsity of charge carriers means devices made from the material have low parasitic capacitances. In other words, there are few charges around, so those charges are unlikely to interact in ways that sap a device’s performance.

The transceiver architecture we’re targeting is called a low-intermediate-frequency heterodyne. (In Greek, hetero means different, and dyne means power.) To unpack what that means, let’s follow an incoming signal through the receiver side of the system. Radio signals from the antenna are boosted by a low-noise amplifier, then fed to a mixer. The mixer combines the received signal with another frequency close to the signal’s carrier frequency. This mixing creates a signal at two new intermediate frequencies, one higher than the carrier and one lower. The higher frequency is then eliminated by a low-pass filter. The remaining intermediate frequency—which is more suitable to processing—is amplified and then digitized by an analog-to-digital converter, which delivers the resulting bits, representing the received signal, to a digital processing unit.

How we actually implemented the RF circuits that performed all these functions was determined by the high-frequency performance of silicon carbide bipolar junction transistor (BJT) technology developed in-house at KTH. That technology resulted in the fundamental RF circuits needed to build a transceiver to send and receive 59-megahertz signals—a balance between the transistor’s high-frequency limits and the constraints of the circuit’s passive components, which get more restrictive at lower frequencies. (This frequency is roughly in the range of the 80 MHz that the Venera landers used. A modern Venus mission is likely to be sending its data first to a satellite orbiting the planet, which could then use NASA’s deep-space frequencies to carry the data home.)

One real make-or-break part of the transceiver is the mixer, which downconverts the 59-MHz signal to a 500-kilohertz intermediate frequency. The heart of our mixer is a SiC bipolar junction transistor, with both the incoming 59-MHz RF signal and a 59.5-MHz signal as its inputs. The output, from the transistor’s collector terminal, connects to a network of capacitors and resistors—all designed to withstand 500 °C—that filter out the high frequency, leaving only the 500-kHz intermediate frequency.

Heat flows through a silicon carbide gate driver chip during testing.

Image: University of Arkansas

Compared to the low-frequency analog and digital circuits that come after the mixer, the RF circuits brought challenges at all stages of development, including the absence of accurate models of the transistor, issues with matching impedances to ensure the most signal gets through, and the reliability of resistors, capacitors, inductors, and PCBs.

Those PCBs, by the way, look nothing like what you’re used to. The ubiquitous FR-4 circuit boards that underpin everything from handheld gadgets to high-end servers would quickly sag and come apart under Venusian conditions. So we use what’s called a low-temperature cofired ceramic board instead. Chips attach to this rock-hard board with gold wires, instead of aluminum, which would soon soften. Silver interconnects, some coated in titanium, link the components into a circuit instead of copper traces, which would pull away from the PCB. Inductors are made on the board as spirals of gold. (Yes, these circuits would be pretty expensive.)

Crucial as the mixer is, a future Venus rover will need a lot more than that. So far, between the University of Arkansas and KTH, we’ve designed, built, and tested some 40 different circuits for 500 °C conditions. These circuits include other RF and analog parts of the transceiver and many of the digital circuits needed for processing data from the transceiver and future planetary-science sensors. Some of these will be familiar to many engineers, such as a 555 timer, an 8-bit analog-to-digital converter and digital-to-analog converter, a phase-locked-loop circuit, and a library of Boolean logic circuits. We admit that since these are university-produced parts made in small numbers, long-term testing has not yet been attempted. Our labs have done at most a week or two of operation at high temperature. However, we’re encouraged by other groups’ extended experiments and take those to indicate that our circuits and devices could operate for longer.

Notably, NASA Glenn Research Center recently reported silicon carbide ICs, with nearly 200 transistors per chip, that operated for a full 60 days in that center’s Venus environment chamber. The chamber subjected the transistors to 9.3 megapascals of pressure, 460 °C heat, and the planet’s particular caustic atmosphere. Not one of those transistors succumbed, suggesting they could have soldiered on much longer had more time in the chamber been available.

There is still a lot of work to be done. We need to focus on integrating the various circuits that have been developed and on improving the yields of working circuits. We must still develop more circuits and prove that they can operate together for months or years with the needed stability at Venus surface temperatures. This last point is particularly important if silicon carbide radios and other low-power circuits are ever to make sense in commercial applications such as jet and natural-gas turbines. With enough effort and priority, these could be years away, not decades.

Will silicon carbide circuits be ready for a future Venus mission? You might more reasonably argue that the mission won’t be ready without them.

This article appears in the May 2021 print issue as “Venus Calling.”

The is article was corrected on 19 May 2021 to give the proper atmospheric pressure at the surface of Venus.