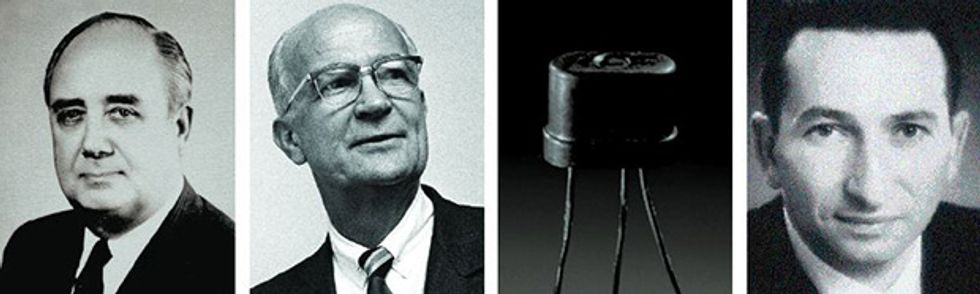

In the Beginning: Gordon Teal (far left) directed the development of the silicon transistor at Texas Instruments. William Shockley (second from left) led the team at Bell Telephone Laboratories that developed the very first transistor, which was made of germanium. TI’s silicon device (second from right) with its three long leads became famous, making the Texas upstart the sole supplier of silicon transistors for several years in the 1950s. Morris Tanenbaum (far right) at Bell Labs actually made the first silicon transistor, but he felt “it didn’t look attractive” from a manufacturing point of view.

Photo: Texas Instruments (Teal, Shepherd, and Transistor); Morris Tanenbaum

The speaker’s words were at once laconic and electrifying. “Contrary to what my colleagues have told you about the bleak prospects for silicon transistors,” he proclaimed in his matter-of-fact voice, “I happen to have a few of them here in my pocket.”

Silicon transistors? Did he say silicon transistors?

Yes—among the few in the world at that moment. It was 10 May 1954.

A long and till-then uneventful session on silicon devices had been winding down at the Institute of Radio Engineers (IRE) National Conference on Airborne Electronics, in Dayton, Ohio. There, a parade of engineers and scientists were lamenting the sobering challenges of developing and eventually manufacturing silicon transistors. Amid the torpor, scattered attendees were stifling yawns, glancing at watches, and nodding off. But that was before Gordon Teal of Texas Instruments Inc. made his surprising announcement—and jaws dropped in disbelief.

“Did you say you have silicon transistors in production?” asked a stupefied listener about 10 rows back in the audience, which now began to perk up noticeably.

“Yes, we have three types of silicon transistors in production,” Teal replied, pulling several out of his pocket to the general amazement and envy of the crowd. Then, in a bit of quaint but effective razzle-dazzle, he cranked up a record player, which began blaring out the swinging sounds of Artie Shaw’s big-band hit, “Summit Ridge Drive.” Amplified by germanium transistors, the music died out instantly as Teal dunked one into a beaker of hot oil. But when he repeated his demonstration immersing a silicon transistor instead, the music played on without faltering.

As his talk ended, Teal mentioned that copies of his paper on the subject, innocuously titled “Some Recent Developments in Silicon and Germanium Materials and Devices,” were available near the rear door. A crowd stampeded back to get them, leaving the final speaker of the session without an audience. Minutes later, a Raytheon engineer was overheard in the lobby shouting into a telephone: “They’ve got the silicon transistor down in Texas!”

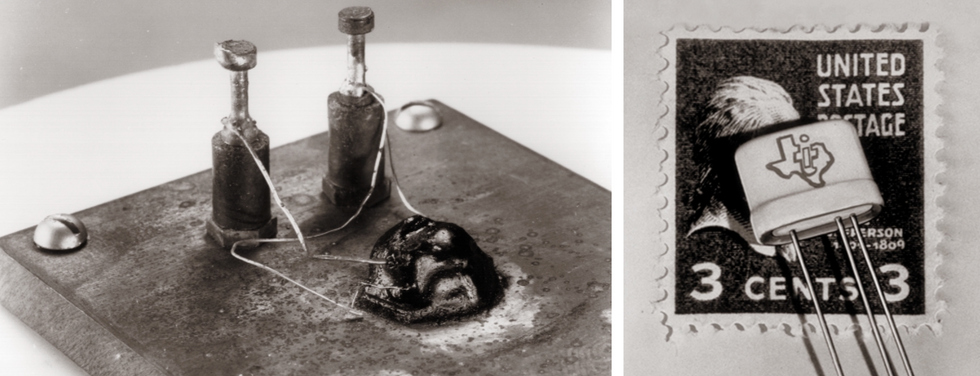

At the time, the silicon transistor seemed to be one of the first major breakthroughs in transistor development not to occur at Bell Telephone Laboratories in Murray Hill, N.J., where physicists John Bardeen and Walter Brattain had invented the transistor in December 1947. Their device featured two closely spaced metal points jabbed delicately into a germanium surface—hence its name, the “point-contact” transistor. They called one point the “emitter” and the other point the “collector,” while a third contact, known as the “base,” was applied to the back side of the germanium sliver. A positive electrical bias on the emitter enhanced the conductivity of the germanium just beneath the collector point, amplifying the output current that flowed to it from the base.

Bell Labs achieved a long string of firsts in the years following that momentous invention, which it announced six months later at a 30 June 1948 press conference in New York City. Among its major advances was the so-called junction transistor [see photos, “Transistor Firsts”], first conceived the previous January by William Shockley, who led the group that included Bardeen and Brattain. He figured that much better transistor performance and reliability could be realized by eliminating the fragile point contacts and instead forming the emitter, base, and collector as a single semiconductor sandwich with three different layers [see sidebar, “Transistors 101: The Junction Transistor”]. But—partly because the frequency response of early junction transistors was inferior to that of point-contact devices—Bell Labs held off announcing this achievement for over a year, until 4 July 1951. Five years later, Bardeen, Brattain, and Shockley shared the Nobel Prize for inventing this revolutionary solid-state amplifier.

Their brilliant pioneering work has overshadowed much of the subsequent development years of the transistor, including the crucial change from germanium to silicon in the mid-1950s. That shift in semiconductor material proved essential to the device’s glorious future as the fundamental building block of virtually all of today’s integrated circuits. For germanium, to put it simply, was just not up to the task.

The material does have advantages: it is far less reactive than silicon and much easier to work with because of its lower melting temperature. And current carriers—electrons and holes—flow through germanium more rapidly than through silicon, which leads to higher frequency response. But germanium also has serious limitations. For example, it has a low band gap (0.67 electron volts versus 1.12 eV for silicon), the energy required to knock electrons out of atoms into the conduction band. So transistors made of this silvery element have much higher leakage currents: as the temperature increases, their delicately balanced junctions become literally drowned in a swarming sea of free electrons. Above about 75 °C, germanium transistors quit working altogether. These limitations proved bothersome to radio manufacturers and especially the armed services, which needed stable, reliable equipment that would perform in extreme conditions.

Nowhere were these concerns appreciated more than at Bell Labs, which led the way into silicon semiconductor research during the early 1950s. Working in its chemical physics department with technician Ernie Buehler, Teal grew single crystals of silicon and “doped” them with tiny impurities to make solid-state diodes in February 1951, publishing the results a year later. He added specific impurity atoms to the molten silicon to alter the electrical properties of crystals drawn from it. Elements from the fifth column of the periodic table—arsenic or antimony, for example—create an excess of electrons in the tetrahedral crystal structure, yielding n-type silicon. Elements from the third column, such as boron or gallium, create a deficit of electrons (usually regarded as an excess of holes), yielding p-type silicon. By adding first one kind of impurity and then the other to the molten silicon from which they slowly withdrew the crystal, Teal and Buehler formed transition regions called pn junctions between the two types of silicon. Small bars cut across these junctions act as diodes when a potential is applied across them through electrical contacts on the two ends.

Meanwhile, Calvin Fuller was beginning experiments in an adjacent lab on diffusing impurity atoms from hot gases into the germanium or silicon surface—one of the major technology milestones on the road to the integrated circuit. By December 1953 Fuller was so successful that Shockley started building a new research team to attempt to fabricate silicon transistors using the technique. And early in 1954, Fuller and Gerald Pearson formed pn junctions by diffusing a thin layer of boron atoms into a wafer of n-type silicon, making a hole-rich p-layer on its surface. These large-area diodes generated substantial current when sunlight fell on them. On 25 April, Bell Labs trumpeted this achievement as the “solar battery,” the first photovoltaic cell operating at efficiencies near 10 percent.

By then TI had made its first silicon transistor —under Teal’s general direction. Back at Bell Labs, he had become homesick for his native Texas, where he had grown up a devout Baptist in South Dallas and pursued his undergraduate studies in mathematics and chemistry at Baylor University, in Waco. Restless in Murray Hill, N.J., and looking for more responsibility, Teal responded to an ad in The New York Times for a research director at TI. He met with TI vice president Pat Haggerty, who offered him the position. He began there on 1 January 1953, bringing with him his vast expertise in growing and doping semiconductor crystals.

Under Haggerty’s leadership, TI was moving aggressively into military electronics, then burgeoning with the Cold War in full swing. The Dallas company had been founded during the 1930s as Geophysical Services Inc., developing and producing reflection seismographs for the oil industry. During World War II, it snagged a U.S. Navy contract to supply airborne submarine-detection equipment; afterward it continued to expand its activities in military electronics, reorganizing itself as Texas Instruments Inc. in 1951. By the time Teal arrived, the firm had almost 1800 employees and was generating about US $25 million in annual sales.

“They’ve got the silicon transistor down in Texas!”

The company was also beginning to manufacture what were called grown-junction germanium transistors under the direction of engineer Mark Shepherd. He had attended a 1951 Bell Labs symposium on transistor technology with Haggerty, where he listened to a Teal workshop on growing semiconductor crystals. In early 1952, after much wheedling and cajoling by Haggerty, TI purchased a patent license to produce transistors from Western Electric Co., AT&T’s manufacturing arm, for $25 000. By the end of that year, it was already manufacturing and selling them under Shepherd’s leadership.

Early the next year, Teal was back in Dallas organizing TI’s research department. Haggerty had hired him to build a team of scientists and engineers that could generate enough ideas and technologies to keep the firm poised at the leading edge of the exploding semiconductor industry. Teal was up to the challenge. He was introverted and difficult to work with, but also smart and stubborn. These qualities had served him well at Bell Labs, where he pursued his crystal-growing research in the late 1940s, working doggedly after hours with almost no support from management. Perhaps most important, this pioneering research had made him a minor celebrity in the fledgling industry, which would prove crucial in hiring bright young people for a group he had to create from scratch. “We could never have attracted the stable of people that we did without him,” Shepherd admitted in a 1993 interview. “And we got some really outstanding scientists in those days.”

Among his new hires was Willis Adcock, like Teal a physical chemist with a Ph.D. from Brown University, in Providence, R.I. He had been working for a natural gas company in Oklahoma and joined TI early in 1953. Adcock began leading a small research group focused on the task of fabricating “grown-junction silicon single-crystal and small-signal transistors that would meet military environmental conditions,” according to Teal, who viewed this as the principal short-term goal for his new research department.

It was no easy task at the time. Because of a high melting temperature of 1415 °C and its great reactivity, the molten silicon from which crystals are drawn interacts with just about any crucible that can contain it. Even fused quartz slowly reacts with the melt, contaminating it with oxygen and other impurities that subsequently find their way into the silicon crystal, degrading its electrical performance. And most of the silicon samples then available from suppliers came with substantial impurities.

Unlike germanium, which could be purified using zone-refining techniques so that impurities could be reduced to about one part per billion, the purest silicon available in those days had much higher levels. And while silicon pn junctions had been fabricated for more than a decade, ever since Russell Ohl first achieved this feat at Bell Labs in 1940, making a successful npn or pnp junction transistor from this semiconductor material was far more difficult. [See “The Origins of the pn Junction,” IEEE Spectrum, June 1997.] The main problem was the extinction of so-called minority carriers (electrons in p-type or holes in n-type layers) due to impurities in the base layer. Electrons will easily “recombine” with holes at any impurity centers within the base. Consequently, too few of these minority carriers could survive while crossing this daunting bridge between emitter and collector to achieve sufficient current gain, or amplification, in silicon. The only solution to this problem, other than struggling to purify the silicon, was to make the base layer extremely thin so that the minority carriers would have some chance of making it from one side to the other.

Adcock, Teal, and their team wrestled with these problems for over a year. Then, in April 1954, using a special, high-purity silicon purchased from DuPont at $500 a pound, they managed to grow a suitable npn structure with an emitter region carefully doped to enhance current gain and a p -type base layer about 1-mil (25 micrometers) thick. Cutting a half-inch (1.27-centimeter) bar from this crystal and attaching electrical contacts on the morning of 14 April, Adcock’s group prepared to test it. Soon Haggerty got an excited call from Teal urging him to come see a demonstration. A few minutes later, “I was observing transistor action in that first grown-junction transistor,” Haggerty recalled at TI’s 25th-anniversary celebrations in 1979. It was a defining moment for the budding semiconductor company. Realizing that another company might well achieve the same breakthrough, Teal hurriedly wrote a paper for presentation at the Dayton conference. And held his breath after Bell Labs announced the silicon solar battery later that month.

Another company, in fact, had already fabricated a working silicon transistor a few months earlier. In January 1954, Morris Tanenbaum made one while working as a member of Shockley’s research group at Bell Labs. But the world’s dominant semiconductor company kept this achievement under wraps, while the Texas upstart rushed to announce it.

Tanenbaum had come to Bell Labs in June 1952 after earning degrees in chemistry and physical chemistry at Johns Hopkins University, in Baltimore, and Princeton University, in New Jersey. He started out in the chemical physics department, growing large single crystals of various semiconductors and testing their properties. In late 1953 Shockley invited him to join the team being formed to push toward silicon transistors. Tanenbaum continued working with Buehler, Teal’s former technician, whom he describes as “a master craftsman in building apparatus and growing semiconductor crystals.”

Buehler was working on a technique known as rate growing. The rate at which impurity atoms (such as gallium and antimony) are incorporated from the melt into the crystal depends to a great extent on the crystal’s growth rate—on how rapidly it is being pulled from the melt. Both impurities are present in the melt simultaneously, but the rate at which either one crystallizes out depends on the pulling speed. This process enabled the team to make much narrower base layers, just 13 to 25 micrometers (µm) thick, which proved to be crucial in limiting the extinction of minority carriers. Tanenbaum cut a half-inch bar from one high-purity silicon crystal that Buehler had grown using special samples from DuPont; then he attached an aluminum lead to the narrow base layer and carefully reheated the silicon to restore the layer’s p-type behavior. On 26 January 1954, according to his logbook, he achieved sufficiently high electron current and hence amplification in an npn silicon transistor. “I believe these were the first silicon transistors ever fabricated,” says Tanenbaum, savoring the moment in an interview nearly half a century later.

“When we made these first [silicon] transistors,” he continues, “we thought about patenting the process but determined for two reasons that it wasn’t worth the effort.” For one, others had developed and used similar techniques. And he really did not like the rate-growing process, which had already been patented by General Electric Co. “It just wasn’t controllable,” he adds. “From a manufacturing point of view, it just didn’t look attractive.”

Smart, stubborn, and introverted, Gordon Teal was up to the challenge.

At the time, Shockley’s group was concentrating on adapting the new diffusion process pioneered by Fuller to the fabrication of germanium and silicon transistors. Diffusion seemed much more promising—as indeed it proved to be—because it was substantially more controllable and could yield much narrower base layers, just micrometers thick, and hence transistors that work at higher frequencies. In July 1954 Charles Lee [PDF] made a successful germanium transistor at Bell Labs using diffusion techniques, operating it at up to 500 megahertz. Tanenbaum spearheaded the effort to duplicate this device in silicon, succeeding on 17 March 1955, with an npn transistor that worked at up to 120 MHz.

Thus, there was little enthusiasm for the rate-grown silicon transistors that he had developed, and Bell Labs made no effort to publicize the achievement. Tanenbaum presented his results at the IRE Solid-State Device Research Conference in June 1954. During the question-and-answer session afterward, he recalls, Teal mentioned similar work that had been done at TI—but was cagey about specifics. Later that year Tanenbaum submitted a paper about his research on rate-grown silicon transistors to the Journal of Applied Physics, where it was finally published in June 1955.

By then the semiconductor industry was on the verge of yet another fundamental shift. At the 1955 Solid-State Device Research Conference held that same month, few people mentioned rate-grown transistors. Everyone there was talking excitedly about the newest breakthrough: diffusion. And Shockley was getting ready to leave Bell Labs to start his own semiconductor company focused on silicon transistors.

It is hardly surprising that the silicon transistor was invented twice, in two seemingly independent achievements just months apart. By 1954 the crucial underlying technologies of silicon purification and crystal growth were at a point where the silicon transistor was perhaps inevitable, given the market demands—which were quite different for the two companies. TI was focused on military markets for transistors as replacements for the bulkier and far more fragile vacuum tubes. The U.S. armed services, among its biggest customers, were willing to pay a big premium for transistors that performed uniformly and flawlessly over a wide range of conditions. Bell Labs’ largest “customer” was AT&T’s Bell Telephone System, which needed rugged, long-lived semiconductor switches that were truly “off” when they were supposed to be off. Because of high leakage currents, especially at elevated temperatures, germanium transistors simply could not satisfy either of these important customers.

It is also obvious that the two achievements had common technological roots reaching back to the pioneering crystal-growth research of Teal and Buehler at Bell Labs from 1949 to 1952. Teal brought this expertise with him to TI, although perhaps not the rate-growing techniques developed a bit later by Buehler. The two groups both benefited from the fact that DuPont saw a growing market for high-purity, “semiconductor-grade” silicon and was beginning to supply small samples of the stuff in 1954. In both cases, the road to the silicon transistor had to cross a narrow, high-purity bridge made of the element.

Amidst all else that was happening at Bell Labs in the early 1950s, the first silicon transistor may not have seemed important enough to merit the same public attention given earlier transistors and the solar cell. At the time, the managers were likely looking ahead eagerly to what they considered the real breakthrough: transistors fabricated using diffusion that operated at over 100MHz. And overconfidence may have played a role, too. Bell Labs had habitually kept mum for months after its earlier breakthroughs, thereby permitting its scientists and engineers to work out most of the patentable ramifications before going public.

Whatever the case, the delay allowed fledgling Texas Instruments to leap forward and claim victory in this race. And it stood alone as the first company to manufacture silicon transistors in volume. Thanks to its foresight and aggressiveness, TI had the silicon transistor market essentially to itself for the next few years—and started down the road to becoming the international giant we know today.

To Probe Further

For the Bell Labs angle on transistor invention and development, see “The Transistor” by J. A. Hornbeck, in A History of Engineering and Science in the Bell System: Electronics Technology (1925–1975) edited by F.M. Smits (Murray Hill, N.J.: AT&T Bell Laboratories, 1985), pp. 1–100.

A broader look at semiconductor history can be found in Crystal Fire: The Birth of the Information Age by Michael Riordan and Lillian Hoddeson (New York: W.W. Norton and Company, 1997).

More technical discussions are available in: “The Invention of the Transistor” by Ian Ross, Proceedings of the IEEE , Vol. 86, No. 1 (January 1998), pp. 7–28.

“Single Crystals of Germanium and Silicon—Basic to the Transistor and Integrated Circuit” by G.K. Teal, IEEE Transactions on Electron Devices, Vol. ED-23, No. 7 (July 1976), pp. 621–39.