If you think about what happens when the bias voltage varies with time, the magic begins to make sense. When the bias voltage is close to zero, the output will of course be very muted. When the bias is significant, the output will be large if the input is large and small if the input is small. In other words, by changing the bias, you can modulate whatever signal you apply to the input.

You could, for example, use this mechanism to shift your voice up to radio frequencies by attaching an RF oscillator to the input and using the voice signal to adjust the bias voltage. A MEMS resonator can be used equally well to shift frequencies in the other direction and down-convert the RF picked up on a radio’s antenna: Just direct the captured RF to the input electrode of the resonator and hook up a suitable RF oscillator to the bias terminal. The MEMS device will automatically filter the output, too, passing only signals that are close to its resonant frequency. If the down-converted and filtered output of the resonator is too weak, increase the amplitude of the oscillating bias voltage; if it’s too strong, use a smaller bias. As you can see, it’s easy to control the operation of such an all-in-one MEMS radio stage.

Just as integrated circuits overtook discrete transistors decades ago, collections of MEMS devices—integrated micromechanical circuits—may eventually become common in wireless handsets. Designers could, for example, combine a large number of MEMS resonators to create a bank of elements each capable of selecting a single communications channel instead of a broad band containing a confusion of signals picked up by the antenna. Providing a radio with filters that could separate out hundreds or even thousands of individual channels has been unthinkable before now. With MEMS, such separation becomes possible.

This strategy is very different from what goes on in the front end of a typical radio set, which uses tunable electronic circuitry to select which of the many frequencies captured by the antenna is sent on to subsequent amplifying and processing stages. It’s also different from what’s proposed for software-defined radios, which is to separate the signals on different channels computationally.

Doing channel selection mechanically would, like the computational approach, allow a smart radio receiver to monitor many different channels simultaneously, allowing it to identify in real time which slices of spectrum are free. The advantage of doing this with a bank of MEMS resonators is that they would draw very little power while doing their job, whereas the purely computational approach, even when it becomes feasible, seems destined to leave our handsets too often with dead batteries.

Using MEMS devices to replace typical front-end radio circuitry is very much still in the active research phase, but virtually all the handset makers are funding work in this area, as is the Defense Advanced Research Projects Agency. So some very sophisticated mechanical radio stages will very likely make the leap from lab bench to marketplace within the next few years.

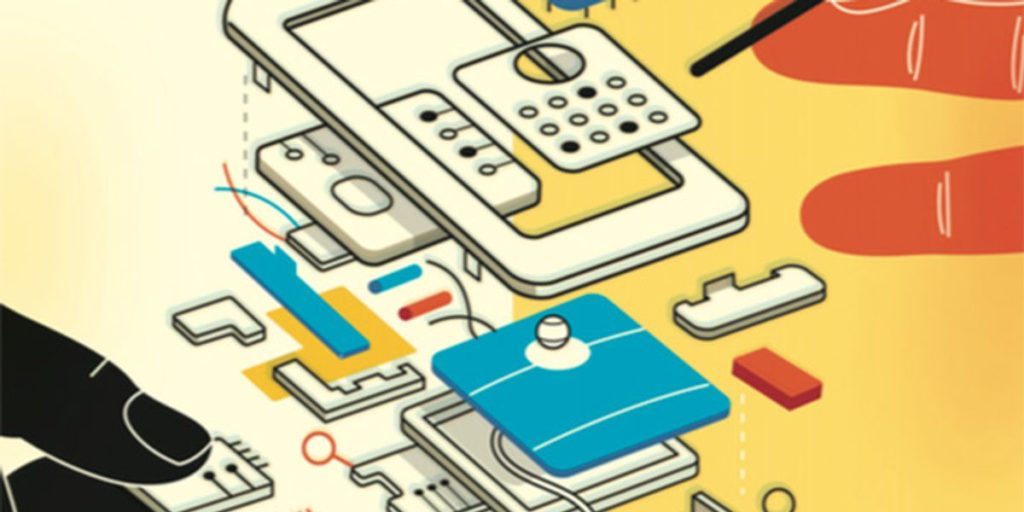

These complex micromechanical devices will not only be integrated together; they’ll most likely be put on the very same chip with electronic circuitry. This combination is possible because the fabrication processes used to create these tiny moving parts—depositing various materials in thin layers and patterning them in complex ways—is so similar to what’s done in making complementary metal-oxide semiconductor (CMOS) circuits.

For example, Analog Devices, in Norwood, Mass., currently makes MEMS accelerometers and gyroscopes with mechanical and electronic components together on the same chip. This is awkward to do, though. The problem is that the construction of MEMS components requires high temperatures that would damage the copper or aluminum traces used in the electronics. So you have to lay down the mechanical parts first before putting down metal. Because most foundries won’t work with wafers that are anything but pristine silicon, this arrangement prevents MEMS-device manufacturers from outsourcing the construction of the electronics and taking advantage of industry-wide advances in CMOS fabrication.

Analog Devices mixes MEMS and CMOS fabrication on a single wafer, first doing some of the steps needed for the transistors, then some for the MEMS, then returning to the transistors, and so forth. It would be better to arrange things so that all the CMOS circuitry is created first with the MEMS on top. Some researchers have done that by bonding a MEMS device to a CMOS chip using tiny wires. My colleagues and I have lately been exploring a different strategy: building the resonators out of metal, which can be laid down at temperatures low enough to avoid ruining the underlying electronics.

Whatever system eventually wins out, it’s a good bet that the highly integrated chips that go into radios will slowly evolve from purely electronic devices into ones that are a complex mixture of electronic and mechanical components. The handset you carry a few years from now might not look very different from the one you have at the moment, but if you’re technically savvy, you’ll appreciate that it performs much better, thanks to internal mechanical parts. If you appreciate that fact enough, you might even be tempted to dress up your cellphone on the outside with a few brass levers or steel gears.

This article originally appeared in print as “Mechanical Radio.”

About the Author

Clark T.-C. Nguyen argues in ”Mechanical Radio” that machining micromechanical parts into our electronics devices will lower their power consumption and make them more robust. It’s about time for micromechanical circuits to have their day, he says: ”You can see it starting up.” Nguyen, who has pioneered advances in MEMS communication technology through his start-up company, Discera, and as a program manager in DARPA’s Microsystems Technology Office, is a professor of electrical engineering and computer sciences at the University of California, Berkeley, where he received his B.S., M.S., and Ph.D. degrees.