Image recognition technology using artificial intelligence (AI) to discern target and non-target shapes is finding uses in aquaculture and fish processing.

Two such recent applications are the Automated Fish-Counting System developed by Osaka, Japan-based Yanmar Marine Systems Co., Ltd. (YMS) and ImageAnalyzer Ceres-II by Tokyo-based CDEX.

YMS is a member of the Yanmar Group, known for its diesel engines and for applications of the engines in agricultural machinery, construction equipment, energy systems, and boats. The group has recently been developing high-tech products for aquaculture, including a robotic underwater net-washing system that operates similarly to some newly introduced pool-cleaning robots.

YMS’ current fish-counting product was developed in collaboration with the aquaculture division of Tokyo-based seafood company Maruha Nichiro Co., which arranged several sites for Yanmar to conduct trials under various environmental conditions to evaluate the product’s performance.

YMS’s system was designed for tuna farming and utilizes image recognition technology to count the fish. In fish farming, it is essential to know the number of fish inside each net in order to control the production volume and the amount of feed supplied.

Additionally, in recent years as part of a shift to more sustainable resource management, fishing vessels are required to accurately report the number of juvenile pacific bluefin tuna caught in the wild, which are later are transferred live to fish farms. The conventional method involves manual counting when the fish are caught and visually counting underwater images when the fish are moved to aquaculture nets. The YMS Automated Fish-Counting System significantly reduces the time and human labor needed to count fish at this transfer stage, the company says.

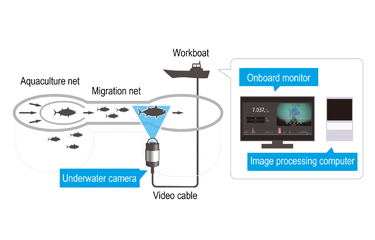

Yanmar’s Research and Development Center developed the image-recognition and processing technology used in the new product, as well as its hardware, including a specially designed underwater camera and image-processing computer used for real-time automated counting. The system works as fish pass from one net to another via a migration net and a camera – attached by video cable to the image-processing computer and an onboard monitor on a workboat – films the fish from below, so that they appear dark against the light of the sky above. The angle of the underwater camera can be adjusted by remote control. The system has a screen display and correction function to allow manual counting and correction in case of environmental disturbance. Under optimal conditions, the system has succeeded in automatically counting tuna with an accuracy of over 98 percent.

Yanmar Global Expert spokesman Paul Bartels acknowledged the system can have minor problems in some circumstances, but that the equipment has redundancies to allow for a more accurate count, if needed.

“Cloudy water conditions can cause problems for the system. Also, when fishes’ bodies overlap, it can be difficult to distinguish individual fish. In these situations, another feature of the system is that it allows for a manual video recount after the fish have passed through the video scanner,” Bartels said.

YMS began accepting domestic orders for the system on 20 April, 2021. Bartels said the price will range for the system ranges from JPY 6 million to JPY 9 million (USD 54,829 to USD 82,251, EUR 44,820 to EUR 67,230), depending on the specifications. At the moment, the company is focused on the bluefin tuna market, but Bartels said that it is looking into the possibility of using the system with other fish.

A competing technology to such a system would be a multi-transducer sonar tuna counting system as described in a recently published scientific paper, “Development of a New Monitoring Methodology for Counting Bluefin Tuna in Net Pens.” The authors of this paper similarly claim an approximate 2 percent error rate for their invention, which is sonar-based, making it less affected by water turbidity. In this system, the fish are counted as they swim in circles inside the pen, rather than as they move across a migration net.

The other image recognition system recently introduced to the market is CDEX’s ImageAnalyzer Ceres-II, which was debuted at Japan Seafood Expo Osaka 2021 in mid-March.

CDEX specializes in designing and developing custom systems for radio frequency identification (RFID), field-programmable gate arrays, which are integrated circuits designed to be configured by a customer or a designer after manufacturing, and large-scale integration and communication systems.

At the show, the system was able to identify the position of foreign matter (plastic fishing worms) in a plate of salmon roe. The system was effective even when the plate was moving and rotating.

The accuracy and processing capacity can be configured according to the detection target, according to CDEX representative Akihiro Terui. The system, which utilizes image-processing and machine-learning technology, can be customized to support various applications, such as mozuku seaweed (Cladosiphon okamuranus), baby sardines, or sakura shrimp.

High-definition image video input from the camera is processed by AI in real-time to detect foreign matter contamination in the target group. Then, the system shows the location of the contamination on the screen, and it has the ability to pass the location to a subsequent system with Modbus TCP interface on TCP/IP. Modbus is one of the more-popular protocols used in the industrial world.

Foreign-matter detection is identified with an accuracy of 97 percent. The system can be controlled by a graphical user interface (GUI).

“The system costs about JPY 2 million per year [USD 18,200, EUR 14,900]. No systems have been sold yet, but the company is currently in negotiation with a customer candidate,” Terui told SeafoodSource.

Image courtesy of Yanmar