In the May 2002 issue of this magazine, the late Lester F. Eastman and Umesh K. Mishra made the case for what was then a long-shot technology in the world of power semiconductors: gallium nitride (GaN). They presented an optimistic outlook for powerful, rugged radio-frequency amplifiers in the then-nascent broadband wireless networks and in radar, as well as in power-switching applications for the electric grid. They called GaN devices “the toughest transistor yet.”

Eastman and Mishra were right. GaN’s wide bandgap—the energy needed to cause bound electrons to break free and contribute to conduction—and other qualities enabled us to exploit the material’s ability to withstand high electric fields, and that led to devices with unprecedented performance.

Today, GaN is the undisputed champion for solid-state RF power applications, and it has arrived in radar, 5G wireless, and will soon be common in the power inverters used in electric vehicles. You can even buy GaN-based USB wall chargers now that have remarkably high power levels for their compact size.

But is there something better? Something that could make RF amplifiers even more powerful and efficient? Something that could shrink power electronics even more, dropping precious kilograms and cubic centimeters of electronics from airplanes and automobiles? Can we find materials with even larger bandgaps that still conduct electricity?

Yes, we can. In fact, there is a universe of materials with higher bandgaps, but peculiarities of quantum mechanics mean that nearly all of them are useless as semiconductors. There is, however, one standout: a transparent conductive oxide, gallium oxide (Ga2O3). At nearly 5 electron volts, this crystal’s bandgap has GaN (3.4 eV) beat by a mile and silicon (1.1 eV) by a marathon. Diamond and aluminum nitride have larger bandgaps, but they don’t have what Ga2O3 has—a fortunate set of characteristics that lend themselves to making inexpensive but very powerful devices.

It’s not enough for a material to simply have a wide bandgap. All dielectrics and ceramics do; otherwise they wouldn’t be of much use as insulators. But gallium oxide has a unique combination of qualities that could make it hugely useful as a semiconductor for power switching and RF electronics.

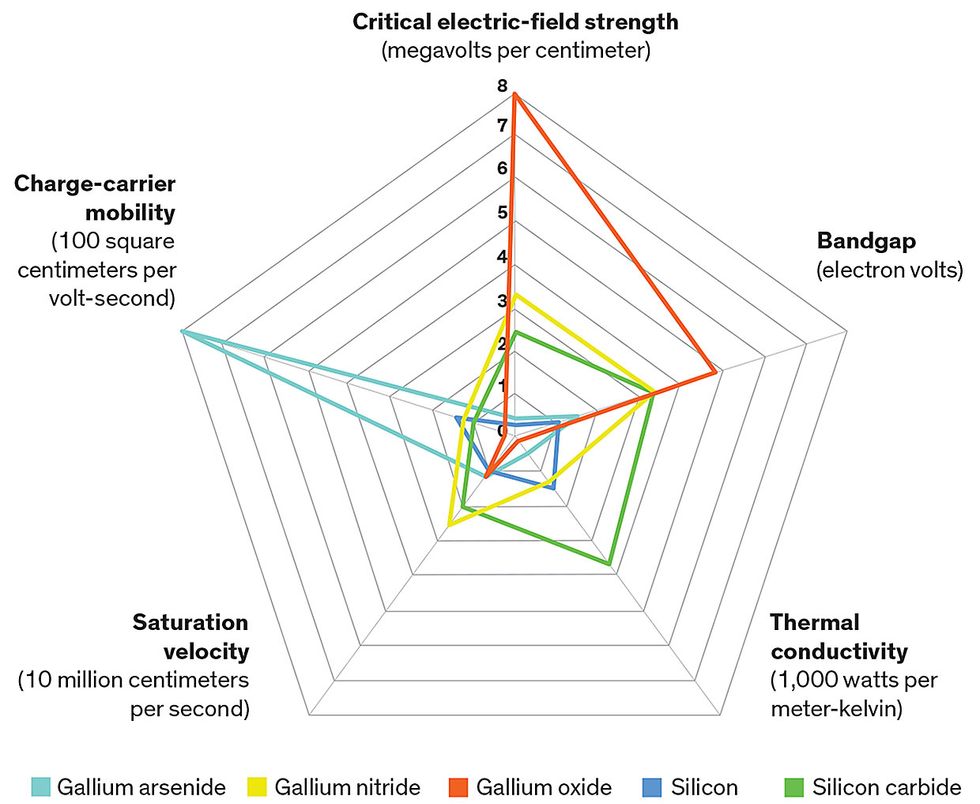

Gallium Oxide in Context: Among the five characteristics that are crucial to semiconductors, high critical electric-field strength is beta-gallium oxide’s biggest advantage. This quality helps lead to high-voltage switches and could mean powerful RF devices as well. However, beta-gallium oxide’s great weakness is a low thermal conductivity, meaning that heat can get trapped inside a device.

Illustration:

IEEE Spectrum Source: ‘Toward Realization of Ga2O3 for Power Electronics Applications,’ by Gregg H. Jessen et al., 2017 75th Annual Device Research Conference (DRC).

One of those qualities is that you can add charge carriers to gallium oxide to make it more conductive by a process called doping. Doping involves adding a controlled amount of impurities to the crystal to manipulate the concentration of charge carriers in a semiconductor. In silicon, you use ion implantation and then annealing to dope the crystal with either phosphorus (to add free electrons) or boron (to subtract them), enabling charges to move freely. In Ga2O3, you can dope the crystal with silicon in the same way to add electrons. Try that in any other wide bandgap oxide and all you get is a smashed-up crystal and spots in the lattice for charge to get stuck.

Gallium oxide’s amenability to dopants added by a standard process called ion-implantation and during epitaxial growth—depositing additional crystal—allows us to borrow a wide range of established commercial lithography and processing techniques. These methods make it relatively trivial to precisely define transistor dimensions in the tens of nanometers and produce all manner of device topologies. Other semiconductor materials with a wide bandgap do not have this incredibly useful feature. Not even GaN can make this claim.

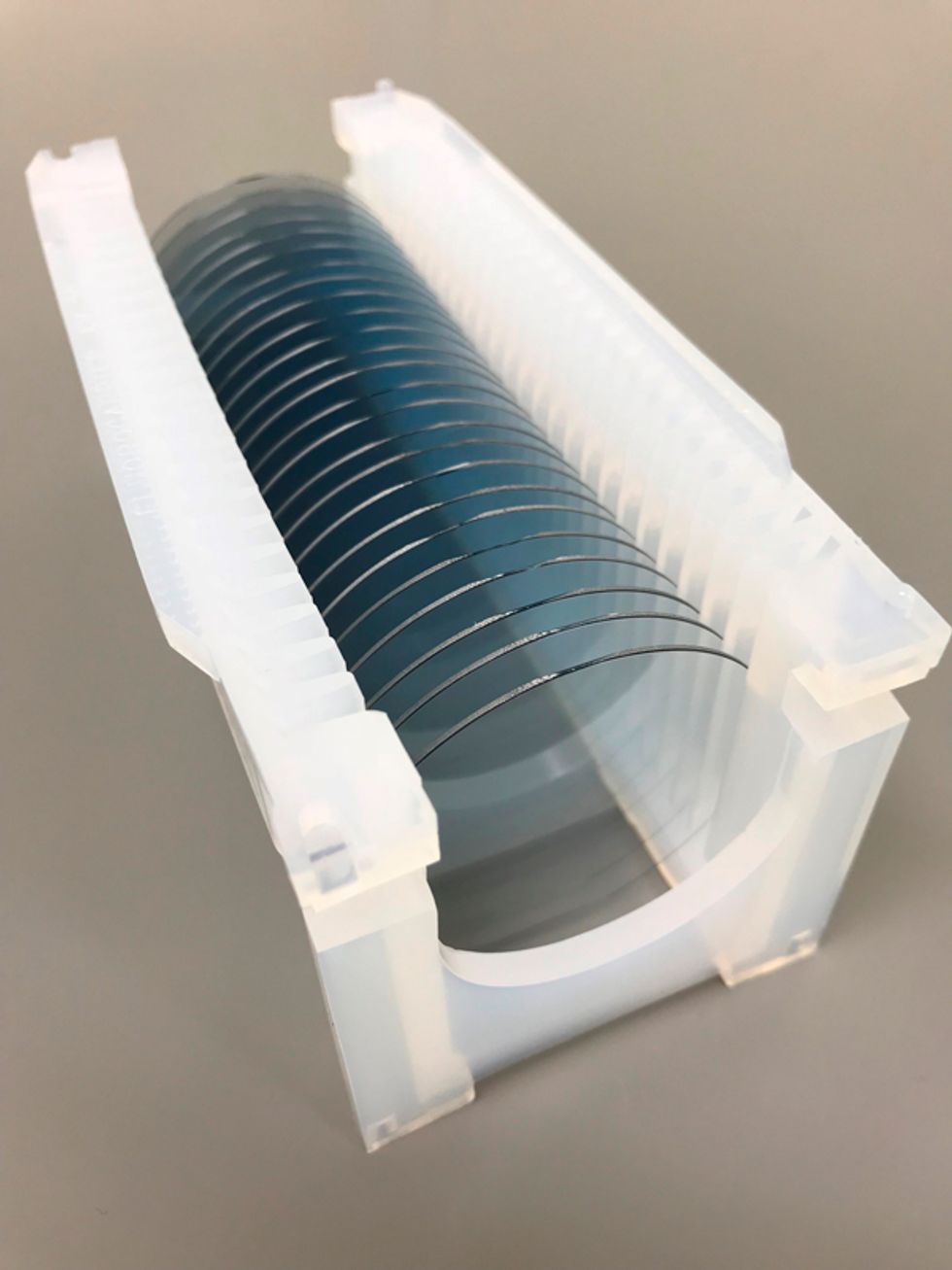

Another advantage is that large wafers of crystalline Ga2O3 are actually pretty easy to make, as these things go. Though there are several types of Ga2O3 crystals, the most stable is designated β, followed by ε and α. Of these, the bulk properties of β-Ga2O3 have been best studied, thanks to pioneering efforts at both the National Institute for Materials Science, in Tsukuba, Japan, and Leibniz-Institut für Kristallzüchtung, in Berlin. What’s particularly interesting about β-Ga2O3 is that its thermal stability allows it to be made using high-volume commercial techniques, including the Czochralski method, which is used to make silicon wafers. β-Ga2O3 wafers can also be produced using a technique called edge-defined, film-fed crystal growth, which is how the sapphire windows are formed for grocery-store checkout bar-code scanners. Nowadays, crystals are even being grown by the highly scalable vertical Bridgman-Stockbarger technique.

It’s hard to overstate how different this situation is from that of other wide-bandgap semiconductors. For all the emerging wide-bandgap semiconductors other than silicon carbide (SiC), there are simply no sizable substrates of the semiconductor on which to grow a large crystal. That means they must instead be grown atop discs of another material, and that comes at a cost. For example, gallium nitride is typically grown in a complex process atop a silicon, silicon carbide, or sapphire substrate. But the crystal structure of these substrates are obviously not the same as that of the GaN, and that difference creates a “lattice mismatch” between the substrate and the GaN that leads to an abundance of defects. These defects create a host of problems for the devices produced. Because Ga2O3 acts as its own substrate, there’s no mismatch, and therefore no defects. Novel Crystal Technology, in Saitama, Japan, has already demonstrated 150-millimeter wafers of β-Ga2O3.

Masataka Higashiwaki at the National Institute of Information and Communications and Technology (NICT), in Tokyo, was the first to recognize the potential of β-Ga2O3 in power switches. In 2012, he surprised the entire semiconductor device community when his team reported the first ever single-crystal β-Ga2O3 transistor. It was a kind of device known as a metal semiconductor field-effect transistor. How good was it? Well, one of the key measures of a power transistor is the breakdown voltage, the point at which the semiconductor’s ability to block the flow of current crumbles. Higashiwaki’s pioneering transistor had a breakdown voltage greater than 250 V. For comparison, it took nearly two decades of development before GaN passed that mark.

In his seminal work, Higashiwaki outlined the case for dramatic reduction in power losses as a result of using a material with a high critical electric-field strength. This characteristic, which is denoted Ec, is gallium oxide’s real superpower. Put simply, if you’ve got a material between two conductors and you crank up the voltage, Ec is the electric field at which the material starts to conduct—a lot—sometimes with catastrophic results. Silicon’s critical field strength is typically measured in hundreds of kilovolts per centimeter, but Ga2O3‘s is 8 megavolts per centimeter.

Having a really high Ec has crucial consequences when you consider the ideal power switching transistor. Ideally, a device would switch instantaneously between two states: all the way on, where it’s conducting with no resistance, and all the way off, where it’s not conducting at all. Those two impossible extremes imply two very different device geometries. For the off state you’d want a thick region of material between the transistor’s source and drain to prevent conduction and block a large voltage. For the on state you’d want an infinitesimally thin region, so it has no resistance.

You can’t have both, of course. It’s the material’s critical electric field strength that determines just how thin this region can really be and still turn off.

The key measure of a semiconductor for low-frequency power switches is called the Baliga figure of merit, named for IEEE Medal of Honor awardee B. Jayant Baliga. In essence, it indicates how well the device’s output reproduces, at high voltage, the details of an input signal. It’s a very important characteristic for transistors operating as switches at frequencies up to the kilohertz range. Such devices are found in multikilovolt-class substation equipment, high-energy photon generators for medical imaging, and power inverters for electric vehicles and industrial motor drives.

For all of these and more, Ga2O3 should have a natural advantage. At these frequencies, the figure of merit is proportional to the cube of the critical electric field. So high Ec means a very good figure of merit. Behind the math is the fact that such a switch spends most of its time either fully on or fully off and little time switching between the two. So most of the power losses are just from resistance to the flow of current when the device is on. With a high Ec, you can use a thinner device, meaning less resistance.

The message from Higashiwaki’s work was simple: You can use brute-force, high-electric-field strength to achieve high-voltage switches that lose little power at low frequencies. Other groups quickly got that message. By 2013, researchers had demonstrated metal-oxide-semiconductor field-effect transistors (MOSFETs) with a breakdown voltage of 370 V. In 2016, Man Hoi Wong, then in Higashiwaki’s group at NICT, had pushed that past 750 V using an add-on structure called field plating. The relative ease with which Ga2O3 achieved high operating voltage in these devices is really quite remarkable; in only a few years research in the material made strides that took decades to achieve with GaN.

But would Ga2O3 be useful in faster-switching power applications? Ec is important here too, potentially giving Ga2O3 a big advantage. At higher frequencies, say 100 kilohertz to 1 megahertz, the device spends proportionally more time switching versus being on or off. Losses during switching are the product of both the device’s resistance and how much charge needs to accumulate on the transistor gate in order to make the switch. Doing the math, that means losses are proportional to the square of critical electric-field strength instead of the cube, as it is for low frequency.

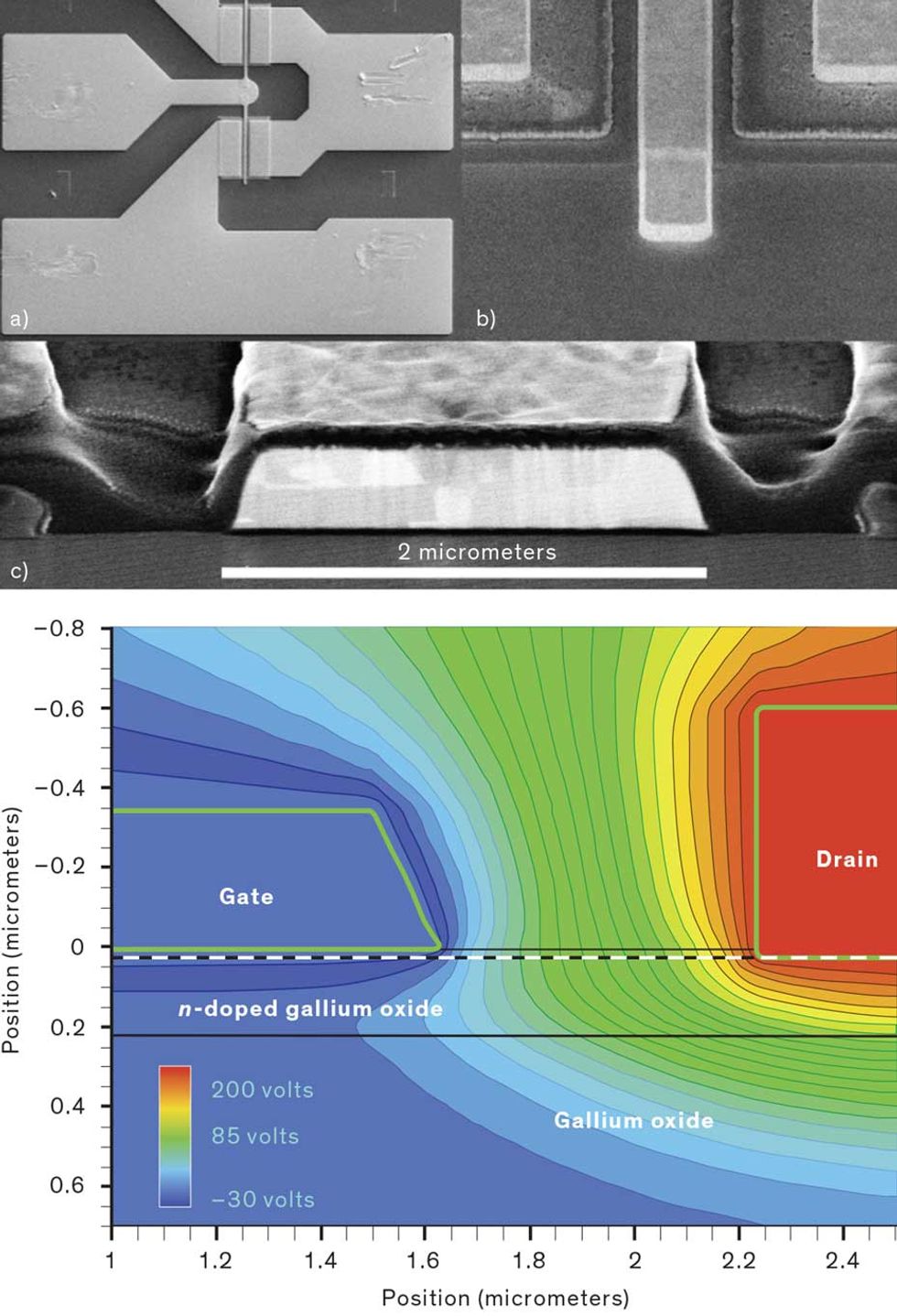

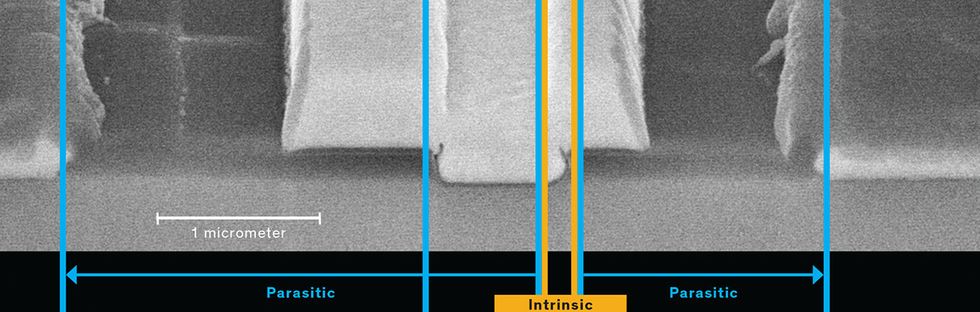

Radio-Frequency Potential: Only a small portion (intrinsic) of this early gallium oxide RF transistor is important to its operation. Reducing the parasitic resistance in the device could boost power and frequency.

Image: Air Force Research Laboratory

You can find the benefits of faster switching in power supplies in things as simple as your phone charger. Switch-mode supplies work by first rectifying AC voltage from the wall plug, then chopping it up into a high-frequency signal. A transformer steps down the voltage to the desired level, and finally the signal is rectified and filtered. The bulkiest part of that system are the transformer and other passive components, and you can use smaller ones only if you increase the frequency. And if it’s a higher frequency you want, a semiconductor with a wider bandgap and higher critical electric field will let you get it much more efficiently while also simplifying the extraction of heat.

For example, a 1200-V silicon inverter switching at 20 kHz can deliver around 3 kilowatts. However, by switching at 150 kHz, a silicon carbide inverter delivering the same power can operate at higher temperature in a package that is one-third the size. A comparable Ga2O3-based inverter could approach the megahertz regime and be half again as small (though that would require as yet uninvented magnetic components).

So, to make a long story short, the real electronic performance of a material such as Ga2O3 comes from exploiting the full critical electric field strength. But what exactly was that value? Until 2015, no group had put a real number on the material’s achievable field strength. And as with every other device, preliminary results are nowhere near the theoretical limit.

My colleagues and I took on that challenge while working at the Air Force Research Laboratory at Wright Patterson Air Force Base, in Ohio. The first problem we encountered was that any device made using a material with such a high field strength has the potential to outperform the limit of the available test equipment. In principle, 2 micrometers of material could block more than 1.5 kV! So we constructed a simple MOSFET with a geometry scaled down for lower voltage; the gap between the gate and drain, where the electric field would be highest, was only 600 nanometers. This was partly to make it easier to measure the peak Ec, but also because we wanted to be able to test the device at RF frequencies, which a larger, high-voltage design wouldn’t allow.

In this early demonstration, the transistor was able to withstand 230 V, which was the limit of the RF test equipment. The resultant mean electric field was at least 3.8 megavolts per centimeter, and simulations indicated a peak internal electric field of at least 5.3 MV/cm. (We were never going to observe the full 8 MV/cm in a FET.) This was the first time that Ga2O3 had been shown experimentally to have a greater EC than the theoretical value for GaN, which is about 3.3 MV/cm. To put that in perspective, a similar GaN power transistor rated for 600-V operation typically has a gate-to-drain gap of around 15 to 20 µm, versus our 600 nm.

After this result, development of power-switching transistors occurred at a blistering pace. In 2017, we made MOSFETs with a breakdown voltage greater than 600 V. In early 2018, MOSFETs using a different geometry achieved high-frequency loss values that met or exceeded the theoretical limits of silicon. What’s more, we now have a clear path toward matching or beating state-of-the-art GaN values in the next couple of years.

Easy Wafer: Unlike many wide-bandgap semiconductors, gallium oxide wafers can be made using roughly the same process that’s used for silicon wafers. So that means defect-free devices could come relatively cheap.

Photo: Novel Crystal Technology

While we were measuring Ec for power switches in 2015, we were also speculating that Ga2O3 might find similar success in RF circuits, again by allowing for higher electric fields in smaller devices. But at that time, there was a piece of critical information missing: There were no published data on electron velocity in the material as a function of electric field.

Electron velocity is particularly important in the transistors used to amplify radio-frequency signals. In RF, high power output and high frequency are the goals, and they’re summed up in Johnson’s figure of merit (JFOM). The JFOM says that the product of power and frequency for an RF transistor scales directly with the product of the maximum velocity of the charge carriers in the semiconductor material and Ec. The key thing to know here is that in an RF transistor, you get amplification only if charge carriers are able to make it all the way from source to drain before the RF waveform’s polarity switches. (The highest frequency at which that happens is called the unity current gain frequency, or fT.) Here again, Ga2O3‘s high critical electric field comes into play, because you can shrink down that critical distance yet still provide a strong electric field to accelerate electrons to their maximum velocity.

At the AFRL, we managed to demonstrate the first submicrometer-size Ga2O3 RF MOSFETs in 2017. These devices posted some pretty impressive figures right out of the gate, though they weren’t quite in GaN’s league. They had a unity current gain frequency of 3 gigahertz and a maximum oscillating frequency of 13 GHz, with an output power density of 230 milliwatts per millimeter at 800 MHz. Since then, AFRL has shown pulsed RF power output density exceeding 500 mW/mm at 1 GHz with maximum oscillating frequency approaching 20 GHz. Even more encouragingly, around the same time, Krishnendu Ghosh and Uttam Singisetti at the University of Buffalo published theoretical calculations suggesting that Johnson’s figure of merit for Ga2O3 is significantly better than that for GaN.

Since that first demonstration of RF capability in 2017, the most notable advances in RF Ga2O3 technology occurred when Sriram Krishnamoorthy, then with Siddharth Rajan’s group at the Ohio State University, demonstrated new and improved doping techniques. Borrowed from silicon, these techniques produced semiconductors with very low resistance in the sheet of material where conduction happens, around 300 ohms per square. (Yes, that’s the correct unit.) That’s comparable to what you’d find in a gallium nitride device. Shortly after this result, Rajan and researchers at the University of California, Santa Barbara, independently demonstrated a Ga2O3 analogue to the high-electron mobility transistor (HEMT).

This type of device, fabricated typically with gallium arsenide or gallium nitride, is an RF mainstay critical to both your cellphone and satellite television receiver. Instead of a doped channel of bulk semiconductor, such devices conduct through a two-dimensional electron gas that forms at the sharp interface between two semiconductors with different bandgaps. In this case it’s aluminum gallium oxide and gallium oxide, which is exactly analogous to commercial aluminum gallium arsenide/gallium arsenide HEMT technology, the kind in smartphones. These critical breakthroughs offer a path toward vertical and lateral scaling for RF devices.

As promising as these developments are, Ga2O3 is unlikely to challenge gallium arsenide (GaAs) or GaN for every RF application. As a fundamentally good switch, we expect it to have an advantage in switch-mode amplifiers, such as Class D, E, or F. In these the device operates with very low on-resistance and capitalizes on low-current, high-breakdown-voltage characteristics to achieve very high efficiency. On the other hand, device applications demanding lower impedance and high current will favor GaN, mainly because its charge-carrier mobility and charge-carrier density is higher.

So what’s wrong with Ga2O3? The Achilles’ heel of this material is its thermal conductivity. It’s bad. Really bad. In fact, it’s literally the worst of all semiconductors under consideration for RF amplification or power switching. Gallium oxide’s thermal conductivity is only about one-sixtieth that of diamond, one-tenth of SiC (the substrate for high performance RF GaN), and about one-fifth that of silicon. (Interestingly, it’s comparable to that RF staple, GaAs.) Low thermal conductivity means heat generated in the transistor is likely to stay there, with the potential to dramatically limit the lifetime of the device.

Now before you throw up your hands in disgust, consider this: To get a real apples-to-apples comparison of a material’s thermal conductivity as it affects devices, you need to normalize it to the ability of the material to handle power. In other words, you need to divide by EC to accurately compare the thermal problems you’d expect in a real device. When you do this, you find that every semiconductor with a bandgap greater than silicon’s has a thermal problem when you use it to its full potential—even diamond. While this fact still doesn’t do Ga2O3 many favors, it motivates us to try to find better ways to dissipate heat.

For example, researchers at the Tokyo lab NICT greatly improved the thermal resistance of a device by bonding p-type polycrystalline SiC to the backside of a Ga2O3 wafer that had been thinned to about 10 µm. And, noting that for certain device topologies virtually all the heat is generated in the top 1 µm of the material, AFRL researchers got promising results simulating the effects of contacting the electrodes and using a dielectric filler to shunt heat to a heat sink. That’s a trick used today in commercial gallium arsenide heterojunction bipolar transistors. So while the thermal challenge in Ga2O3 demands respect, it is nothing that some clever engineering can’t surmount.

A more fundamental problem is the fact that we can only get gallium oxide to conduct electrons and not holes. Nobody has ever managed to make a good p-type conductor out of Ga2O3. And, dispiritingly, the material’s basic electronic characteristics don’t leave much hope. In particular, the valence-band portion of the material’s band structure does not have the right shape for hole conduction. So even if there is a dopant that results in acceptors at the right energy levels, any hole generated is expected to trap itself before it can contribute to conduction. It’s difficult to argue there’s a way around this drawback when theory and data are in such agreement.

Although this weakness does create extra challenges, it’s not a showstopper. Plenty of so-called majority-carrier-only devices have found commercial success. You need look only as far as many USB-C wall chargers for an example.

The research stage of Ga2O3-device technology is just beginning to reach critical mass, and we are now mapping out the application space for fast switches, multikilovolt-class power transistors, and RF devices. New demonstrations of kilovolt-class devices are now a regular occurrence. RF transistors with critical dimensions in the tens of nanometers are forthcoming. I fully expect that as we push this technology, we will be able to realize device topologies that were previously unachievable in any other material.

Sure, we’ll break a few things along the way (mostly dielectrics). But that is the definition of disruptive technology. We trade what we know for potential performance. At the moment, for Ga2O3,the performance potential greatly outweighs the problems.

This article appears in the April 2021 print issue as “The Supercharged Semiconductor.”