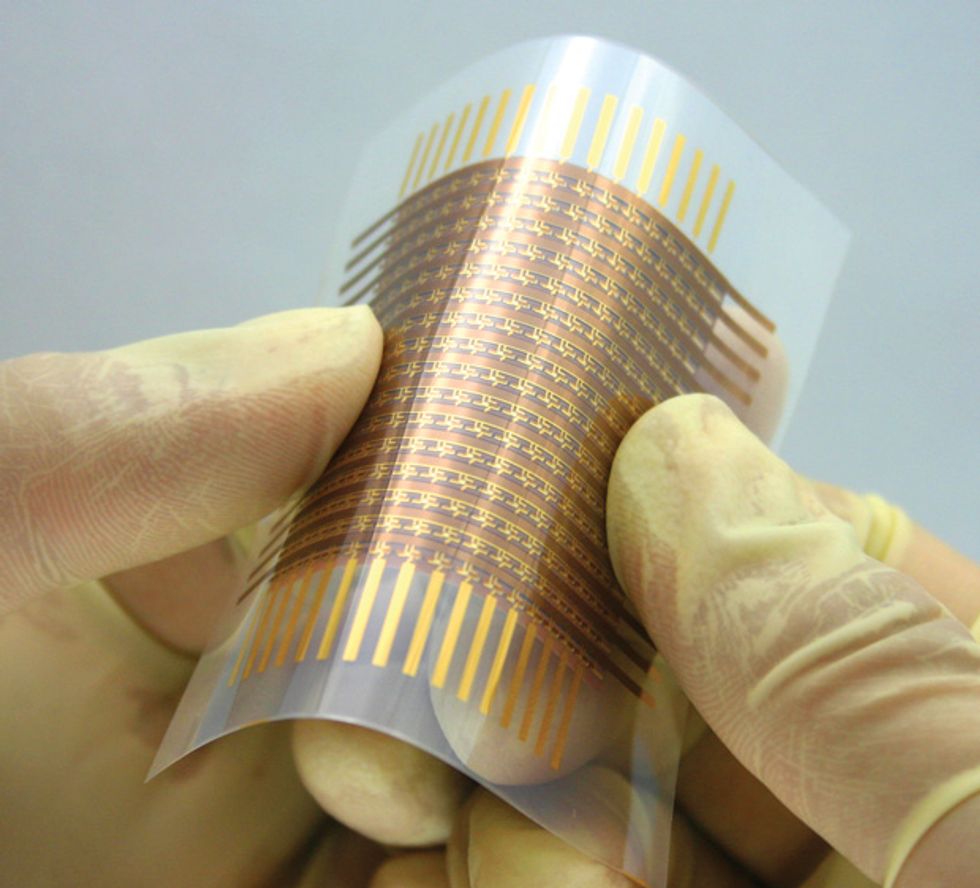

Gilded skin: Takao Someya’s latest e-skin material is one-tenth the thickness of plastic kitchen wrap, and it can conform to any body shape.

Photo: Someya-Sekitani Group

A golden glove: In 2003, Someya’s lab used organic thin-film transistors to create its first flexible, bendable e-skin. Researchers wrapped the material around a mechanical hand to demonstrate the potential applications of e-skin in robotics. The material included pressure and temperature sensors.

Photo: Someya-Sekitani Group(2)

One decade ago, my research group at the University of Tokyo created a flexible electronic mesh and wrapped it around the mechanical bones of a robotic hand. We had dreamed of making an electronic skin, embedded with temperature and pressure sensors, that could be worn by a robot. If a robotic health aide shook hands with a human patient, we thought, this sensor-clad e-skin would be able to measure some of the person’s vital signs at the same time.

Today we’re still working intensively on e-skin, but our focus is now on applying it directly to the human body. Such a bionic skin could be used to monitor medical conditions or to provide more sensitive and lifelike prosthetics.

But whether we’re building e-skin for robots or people, the underlying technological challenges are the same. Today’s rigid electronics aren’t a good fit with soft human bodies. Creating an electronic skin that can curve around an elbow or a knee requires a thin material that can flex and even stretch without destroying its conductive properties. We need to be able to create large sheets of this stuff and embed it with enough sensors to mimic, at least roughly, the sensitivity of human skin, and we need to do it economically. That’s a tall order, and we’re not there yet. But ultimately, I think engineers will succeed in making e-skins that give people some amazing new abilities.

The first step in making e-skins that can bend around a joint is figuring out how to provide electronics with better mechanical flexibility. Modern integrated circuits, including the microprocessors inside computers and the thin-film transistors behind display screens, are manufactured on rigid substrates like silicon and glass. So the things built with these chips—laptops, flat-panel TVs, and the like—are rigid too.

Manufacturers have already commercialized flexible circuit boards for those passive components that are mechanically flexible, such as wiring. But rigid elements like silicon chips and chip capacitors are still attached to these flexible boards. To make an e-skin, we need greater flexibility: Not only the wiring but also the substrate and all the circuitry must be bendable. We need electronics that can be rolled up, folded, crumpled, and stretched.

Thin-film transistors will be one of the key elements in this electronics revolution. These TFTs can be made of various kinds of semiconductor materials that can be deposited in thin layers, such as amorphous silicon, low-temperature polycrystalline silicon, organic semiconductors, and carbon nanotubes. And there is a range of materials that can serve as flexible substrates for TFTs, such as ultrathin glass, stainless steel foils, and plastic films.

After much experimentation, my group has concluded that plastic films are very promising. They’re rugged and hold up well against mechanical strain, they cost very little, and they’re compatible with new manufacturing processes that can produce large, flexible sheets of electronic materials—including roll-to-roll manufacturing methods now being developed. To print TFTs on a plastic film, you need to keep the processing temperature low enough to prevent the plastic from changing its shape. TFTs made with organic semiconductors seem promising in that regard, because they can be printed at room temperature.

Thin-film transistors don’t just allow electronics to be flexible—they can also help an e-skin mimic the sensitivity of real skin. Consider this: There are more than 2 million pain receptors in a person’s skin, which is equivalent to the number of pixels found in a typical high-definition TV. A major obstacle we faced in developing an e-skin was figuring out how many sensors could be integrated into electronic sheets. You can’t wire 2 million sensors directly to the driver circuits that control them, because this would mean cramming 2 million contact pads onto a silicon chip.

Our solution was to do exactly what display manufacturers do to control the transistors in their TV screens. They use wiring layouts that allow the CPU to send commands to the transistors attached to individual pixels based on where they lie in a big conductive grid. Using column and row numbers to specify the pixel’s address reduces the number of connections necessary. A similar “active matrix” strategy can be used in e-skins with millions of embedded sensors.

The next challenge comes simply from the large area you need to cover. The total surface area of an average adult human’s skin exceeds 2 square meters. That’s about twice as big as the largest flat-screen LCD TV you can buy at an electronics store. The conventional semiconductor-fabricating machines used in the flat-panel-display industry, such as vacuum-deposition and photolithography tools, are already quite expensive. It wouldn’t be economically feasible to use these tools in e-skin applications, which would require covering even larger areas.

But there is another way to make large-area electronics that holds great promise, not just for e-skin research but for the semiconductor industry in general. By using inkjet and other printing processes, manufacturers can significantly reduce production costs. For example, inkjet technology can deliver the exact amount of any substance you want applied to precisely targeted positions, which reduces the waste of raw material. Printing processes can simultaneously apply the coating and the circuitry pattern of thin-film materials, which are usually performed as separate steps when semiconductors are manufactured via lithography. Compared with vacuum-deposition methods, which use a huge amount of electricity to pump the air out of a big stainless-steel chamber, printing processes use minimal power.

In 2003, my lab at the University of Tokyo developed organic thin-film transistors that we used to create an e-skin prototype for a robotic hand. The material was functional even when rolled around narrow fingers; however, it couldn’t bend at the finger joints the way real skin would. We included pressure sensors in this first e-skin, but our real achievement was in using an active-matrix layout for the flexible sensor array. This layout would allow the integration of any kind of sensor array without turning the e-skin into an impossible tangle of wires. That same year one of the pioneers of stretchable electronics, Sigurd Wagner of Princeton University, fabricated transistors made of amorphous silicon and metal wiring on a rubber substrate, demonstrating that elastic electronics were a real possibility.

My team was inspired by Wagner’s work, and a few years later, in 2005, we took the next step: making an e-skin that wasn’t just flexible but also stretchable. In our first attempt, we manufactured a sheet embedded with transistors and pressure sensors and then used a mechanical punching process to remove the material between the sensor nodes. This created a netlike structure that could be stretched by 25 percent.

With our next effort, we had even better results. By inventing a printable elastic conductor that can be used for stretchable wires and contacts in integrated circuits, we were able to stretch the material by 140 percent without interfering with its function. We made the conductor out of rubber with carbon nanotubes distributed throughout the material in tangled networks. When the rubber is stretched, those conductive nanotube networks change their shape but do not break. We demonstrated the effectiveness of these conductors by also integrating organic LEDs into the circuits, creating brilliant light-up displays that could be folded in two or curved around a globe.

But human bodies do not fold in simple ways, and our e-skin had to match the body’s marvelous flexibility. So we set our minds to making ultrathin electronics that could flex and also conform to a dynamic, three-dimensional shape. A nearly imperceptible electronic foil, we thought, could one day be as common as plastic wrap is today.

This July we reported the success of our experiments in the journal Nature. We fabricated organic transistors and tactile sensors on an ultrathin polymer sheet that measured 1 micrometer thick—one-tenth the thickness of plastic wrap and light enough to drift through the air like a feather. This material can withstand repeated bending, crumple like paper, and accommodate stretching of up to 230 percent. What’s more, it works at high temperatures and in aqueous environments—even in saline solutions, meaning that it can function inside the human body.

Flexible electronics using organic transistors could serve a range of biomedical applications. For example, we’ve experimented with electromyography, the monitoring and recording of electrical activity produced by muscles. For this system, we distributed organic transistor-based amplifiers throughout a 2-μm-thick film. This allowed us to detect muscle signals very close to the source, which is key to improving the signal-to-noise ratio, and thus the accuracy of the measurements. Conventional techniques typically use long wires to connect sensors on the skin with amplifier circuits, which results in a pretty abysmal signal-to-noise ratio.

And we can imagine more medically urgent applications of such a system. In collaboration with the medical school at the University of Tokyo, we’re working on an experiment that will place our amplifier matrix directly on the surface of an animal’s heart. By detecting electric signals from the heart with high spatial resolution and superb signal-to-noise ratios, we should be able to zoom in on the exact location of problems in the heart muscle that can lead to heart attacks.

Your skin is essentially an interface between your brain and the external world. It senses a tap on the shoulder or the heat from a fire, and your brain takes in that information and decides how to react. If we want bionic skins to do the same, they must incorporate sensors that can match the sensitivity of biological skins. But that is no easy task. For example, a commercial pressure-sensitive rubber exhibits a maximum sensitivity of 3 kilopascals, which is not sufficient to detect a gentle touch.

To improve an e-skin’s responsiveness to such stimuli, researchers are experimenting with a number of different techniques. Zhenan Bao and her colleagues at Stanford University created a flexible membrane with extraordinarily good touch sensitivity by using precisely molded pressure-sensitive rubber sandwiched between electrodes. A novel design of the thin rubber layer, using pyramid-like structures of micrometer size that expand when compressed, allowed the material to detect the weight of a fly resting on its surface. With such structures embedded in it, a bionic skin could sense a breath or perhaps a gentle breeze. This kind of sensitivity would be a great benefit in a prosthetic hand, for example, by giving the wearer the ability to grip delicate objects.

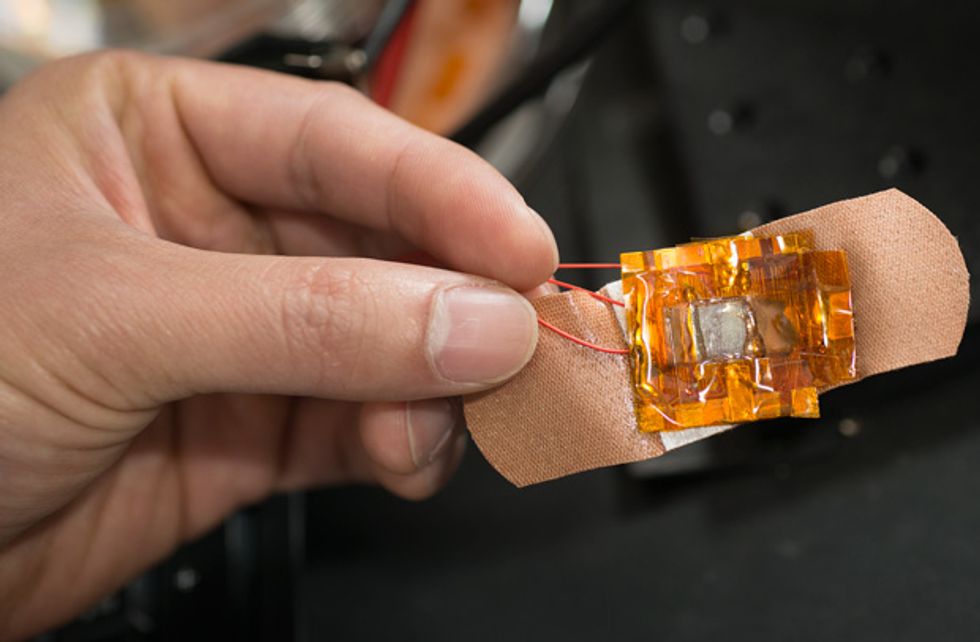

In the most recent application of Bao’s technology, her team turned the pressure sensors around so that instead of detecting external stimuli, they measured a person’s internal functions. The researchers developed a flexible pulse monitor that responds to each subtle surge of blood through an artery, which could be worn on the inner wrist under a Band-Aid. Such an unobtrusive monitor could be used to keep track of a patient’s pulse and blood pressure while in the hospital or during surgery.

And we must look beyond just pressure sensitivity: Biological skin has the critical ability to sense many variables at once. The early e-skins produced by my lab adopted an integrated system that simultaneously detected pressure and temperature, and then mapped those stimuli to particular locations on the skin’s surface. Our flexible thermal sensors relied on organic diodes, whose electronic properties strongly depend on temperature. One day a glove equipped with such sensors might allow you to gauge another person’s emotional response when you shake hands.

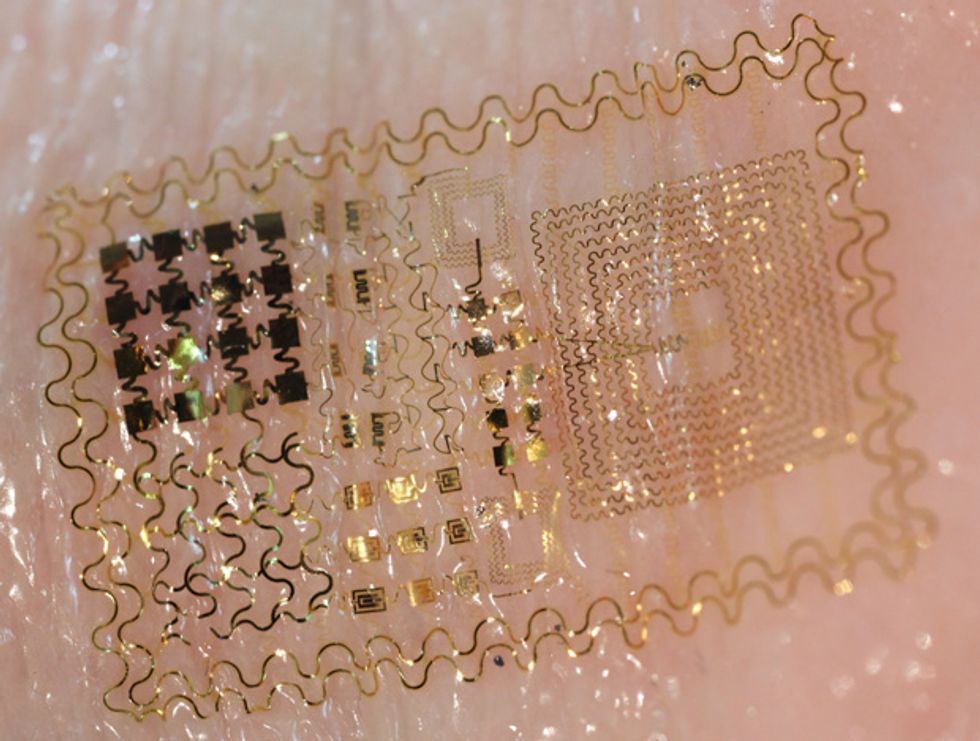

Subtle sensors: John Rogers makes electronic films that stick to the skin or may be laminated on like temporary tattoos. Radio-frequency communication circuits in the material can forward data from sensors on the skin to a computer.

Photo: John Rogers(2)

Why not get even more ambitious? We make cameras that see more clearly than our own eyes, so why not build super e-skins that have more tactile abilities than our own skins? And there’s no need to restrict things to refining human capabilities: An e-skin could also be light sensitive or contain ultrasonic detectors. It’s only a question of adding the appropriate flexible electronics.

My group has developed flexible, large-area ultrasonic sensor arrays that could keep both robots and humans out of trouble. An ultrasonic skin covering an entire robot body could work as a 360-degree proximity sensor, measuring the distance between the robot and external obstacles. This could prevent the robot from crashing into walls or allow it to handle our soft, fragile human bodies with more care. For humans, it could provide prosthetics or garments that are hyperaware of their surroundings.

Besides adding multiple functions to e-skins, it’s also important to improve their electronic properties, such as the speed at which signals can be read from the sensors. For that, electron mobility is a fundamental limiting factor, so some researchers are seeking to create flexible materials that allow electrons to move very quickly.

Ali Javey and his colleagues at the University of California, Berkeley, have had some success in that area. They figured out how to make flexible, large-area electronics by printing semiconducting nanowires onto plastics and paper. Nanowires have excellent electron mobility, but they hadn’t been used in large-area electronics before.

Materials like the ones Javey developed will also allow for fascinating new functions for e-skins. My team has developed electromagnetic coupling technology for e-skin, which would enable wireless power transmission. Imagine being able to charge your prosthetic arm by resting your hand on a charging pad on your desk. In principle, any sort of conductor could work for this, but if materials with higher electron mobility are used, the transmission frequency could increase, resulting in more efficient coupling.

Discreet detection: Zhenan Bao’s pressure sensor, which can be hidden under a Band-Aid, can detect the pulse in a person’s wrist.

Photo: L.A. Cicero

Linking sensors with radio-frequency communication modules within an e-skin would also allow the wireless transmission of information from skin to computer—or, conceivably, to other e-skinned people. At the University of Illinois at Urbana-Champaign, John Rogers’s team has taken the first step toward this goal. His latest version of an “electrical epidermis” contained the antenna and ancillary components needed for radio-frequency communication. What’s more, his electronics can be laminated onto your skin in the same fashion as a temporary tattoo. The circuit is first transferred onto a water-soluble plastic sheet, which washes away after the circuit is pressed on. Doctors could use these tiny devices to monitor a patient’s vital signs without the need for wires and bulky contact pads, and people could wear them discreetly beyond the confines of the hospital.

Rogers and his colleagues tried out a number of applications for their stick-on electronics. In their most astonishing iteration, they applied circuitry studded with sensors to a person’s throat where it could detect the muscular activity involved in speech. Simply by monitoring the signals, researchers were able to differentiate among several words spoken by the test subject. The user was even able to control a voice-activated video game. Rogers suggested that such a device could be used to create covert, subvocal communication systems.

Skins that know what we’re saying without having to say it, skins that can communicate themselves, skins that extend our human capacities in directions we haven’t yet imagined—the possibilities are endless. And while some readers may worry about e-skins being used to invade the privacy of their bodies or minds, I believe the potential benefits of this technology offer plenty of reasons to carry on with the work. For example, the car company Toyota has already demonstrated a smart steering wheel that measures the electrical activity of the driver’s heart; imagine a smart skin that can warn a patient of an oncoming heart attack hours in advance.

Human skin is so thin, yet it serves as a boundary between us and the external world. My dream is to make responsive electronic coverings that bridge that divide. Instead of cold metal robots and hard plastic prosthetics, I imagine machines and people clothed in sensitive e-skin, allowing for a two-way exchange of information. Making our mechanical creations seem almost warm and alive and placing imperceptible electronics on humans will change how people relate to technology. The harmonization of people and machines: This is the cyborg future that e-skins could bring.

This article originally appeared in print as “Building Bionic Skin.”

About the Author

Takao Someya is a professor at the University of Tokyo’s School of Engineering. Someya says that when he presents his research on electronic skins people sometimes get alarmed and raise questions about privacy. Because these e-skins can monitor vital signs and physical activity, they can offer insight into people’s health conditions—and perhaps even their mental states. Someya’s response? The technology could have many practical benefits, if it’s employed responsibly. “This should not be nightmarish,” he says.