Copyright © 2020 Albuquerque Journal

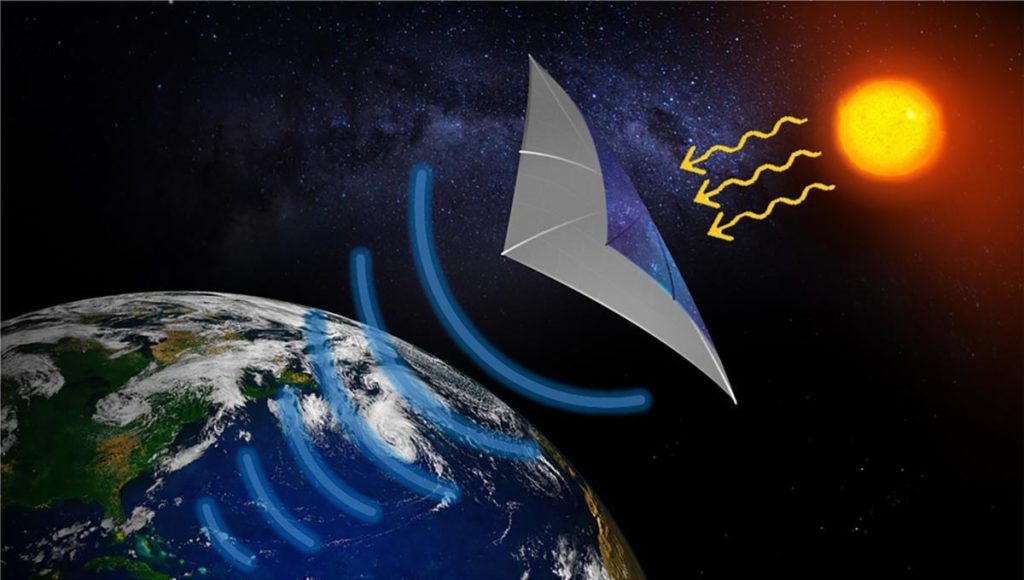

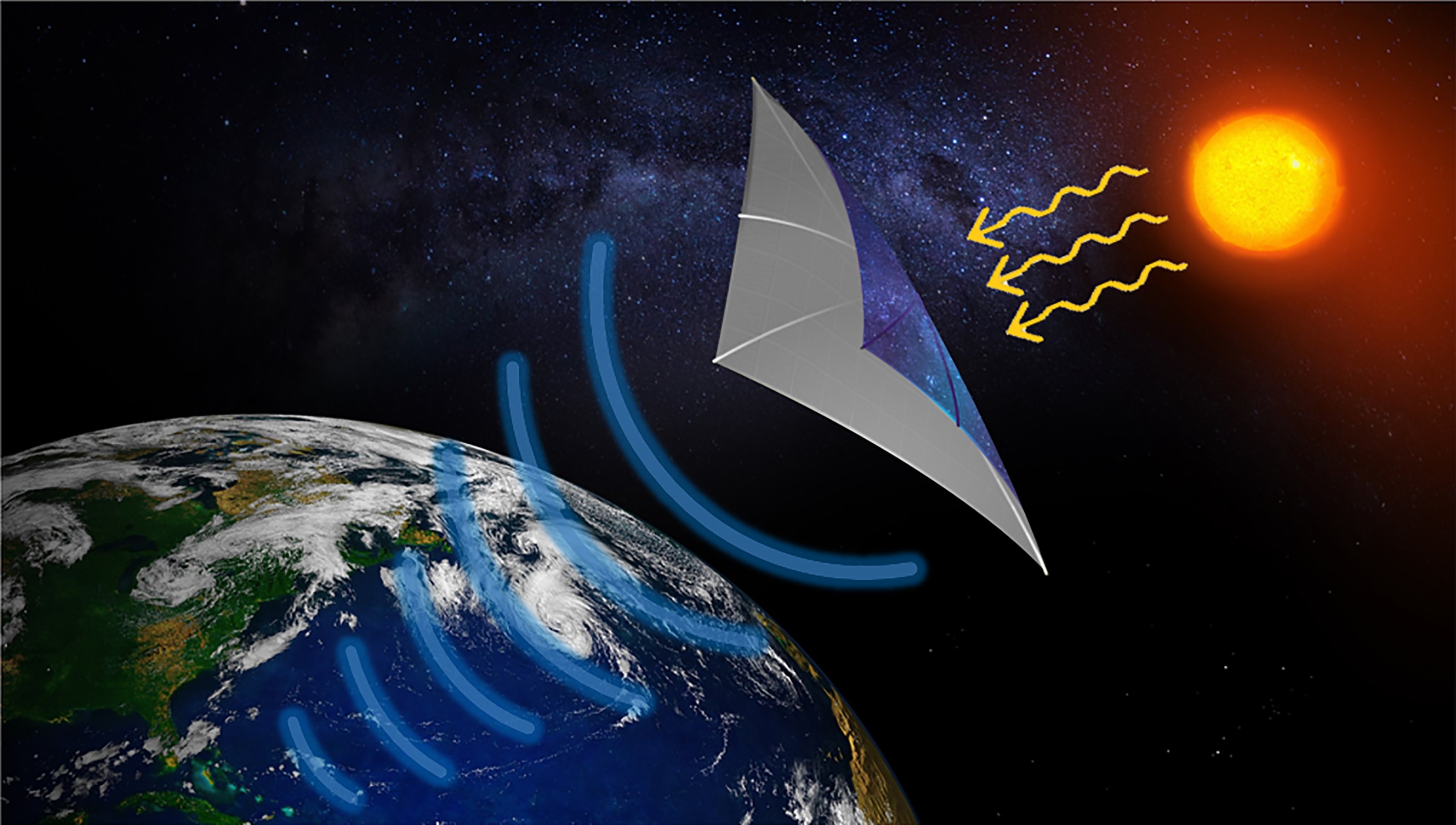

In the near future, solar power collected in space and beamed down to Earth could power military and civilian installations, vehicles and devices in remote places across the globe.

The foundational technology is already in hand, and the first small-scale demonstration project will be ready for launch in 2023, thanks to a broad collaboration between the Air Force Research Laboratory’s Space Vehicles Directorate at Kirtland Air Force Base, the U.S. Department of Energy’s National Renewable Energy Laboratory in Colorado, and private industry partners here and elsewhere.

……………………………………………………….

Apart from providing around-the-clock power on demand beamed from space, the new solar cells, panels and production processes being developed through the program could revolutionize space-based power systems in general and terrestrial photovoltaic installations by offering higher-efficiency systems at much lower cost than is available today.

The potentially “game-changing” technology could become widely available over the next decade, said Col. Eric Felt, head of the Space Vehicles Directorate.

“The technology has reached a point where we believe we can do it,” Felt told the Journal. “We’re in the final maturation phase for the key technologies, and we’ve got a road map for it … We’ve laid out the whole program, and we’re now on a path to build a 2-meter solar system for launch on a satellite in 2023 to prove the technology.”

Old tech, new use

The “spider” project – Space Solar Power Incremental Demonstrations and Research, or SSPIDR – is actually building on technology created decades ago. Photovoltaic beaming, or wireless power transfer, was demonstrated in the 1970s, said SSPIDR project manager James Winter. It’s based on gathering solar energy with photovoltaic cells and then converting it to radio frequency for beaming from antennas to receivers.

That process is used for satellite TV, whereby solar energy is used to propagate radio frequency that’s then sent to the ground for communications. In the case of wireless power transfer, the radio frequency is received by a “rectifying antenna” that converts the frequency back to electricity, Winter said.

“The concept has been around a while,” Winter said. “With normal solar systems, you collect solar energy and convert it to direct current to charge up batteries on a satellite. … With a solar-to-radio-frequency module, there is no storage – you convert the solar energy to direct current and then to radio frequency with integrated circuits for transfer to a rectifying antenna that converts it back to direct current.”

Lowered costs

Space-based solar beaming hasn’t been done before because building the components and integrated systems and then flying them to space is very expensive. But through the DOD’s collaborative program, it’s now working to immensely lower the costs for building, integrating, transporting and operating a system.

That includes development of new, cheaper manufacturing processes for the high-efficiency solar cells needed to operate in space, plus automation of the assembly process for solar panels and systems to replace today’s labor-intensive methods.

Unlike the silicon-based solar cells used in terrestrial applications, photovoltaic for space requires more robust materials that can withstand harsh conditions, and which can produce more electricity from the sun to power spacecraft over long periods of time. Those materials, gallium arsenide and gallium indium, cost a lot more than silicon. And cell manufacturing is based on a very slow process called metal organic vapor phase epitaxy, or MOVPE, which deposits the pre-engineered chemicals onto a semiconductor wafer one layer at a time. Building those robust cells can push user end costs up to $300 a watt, compared with below $1 per watt for silicon cells.

NREL, the DOE’s lab in Colorado, has created a faster, cheaper manufacturing process for those robust cells. It’s also successfully replaced the expensive organic metal compounds with materials that contain aluminum, or pure metal compounds, which are much less expensive, said Space Vehicles Directorate senior physicist David Wilt.

Layered approach

The new manufacturing process is actually a modification of an old process called hydride vapor phase epitaxy, or HVPE, which MOVPE replaced in the 1970s because the latter better managed the delicate layer-by-layer buildup of materials on a semiconductor wafer.

Both processes work one layer at a time. But with MOVPE, the system stops after each layer is deposited to change out the gas mixture, thereby creating different compositions of stacked thin films for each solar cell. In contrast, the old HVPE system completely removed the wafer before changing the gas mixture, and then reinserted it to continue depositing the next compound.

NREL has modified the HVPE process by setting up different chambers side by side so that, rather than removing and reinserting wafers, the wafers move in a continual stream from one chamber to the next as different gas mixes are deposited. The new system, called “dynamic” HVPE, speeds manufacturing significantly, allowing NREL to make multilayered cells up to 20 times faster, Wilt said.

“By moving from chamber to chamber, it puts down materials at up to 500 microns per hour, compared with five to 10 microns per hour with MOVPE,” Wilt said.

The system can be scaled up by adding more chambers.

“Eventually, it will be a linear system where a bare wafer goes in one end and runs through multiple chambers with a full solar cell structure coming out the other end,” Wilt said.

That could massively lower production costs for high-efficiency cells for space applications.

Private sector use?

In addition, NREL hopes to eventually transition the new technology to the private sector, making the manufacturing process available for both defense and commercial purposes, said NREL lead researcher Kelsey Horowitz.

“If we are successful in reducing all the high-cost solar cell fabrication processes, we may enable the use of these high-efficiency cells in broader civilian and commercial applications,” Horowitz said in a statement. “These include applications that require higher power per area and value flexibility, like on ships, electric vehicles or portable devices.”

The Space Vehicles Directorate is also working with SolAero Technologies in Albuquerque to lower the costs for making full solar panels and modules. SolAero, which makes robust solar systems for space, won a $4.5 million contract to develop automated processes for building modules, said Michael Riley, deputy program manager for the Space Vehicles Directorate advanced space power group.

“It’s a very labor-intensive process now aimed at one-off designs for satellites,” Riley said. “We want to automate assembly design for faster, high-volume production of modules for a variety of satellite applications.”

The AFRL is also working on the antenna technology for solar-beaming to create robust metrology to steer precision radio frequency beams wherever needed, said SSPIDR program manager Winter.

“It will offer a continuous power supply, unlike terrestrial systems where darkness and rain interfere,” Winter said. “All you need is a rectifying antenna to receive power from space anywhere on the globe.”