In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, acquisitions, and partnerships in the 3D printing sector.

Today’s edition includes new 3D printing partnerships, a spate of 3D printer deliveries, certifications, and a whole host of new 3D printing materials.

Read on for the most recent updates from SWISSto12, Constellium, Adaptive3D, Kennametal, Recreus, Automation Alley, Wall Colmonoy, Ozark, 3rd Dimension, Intech Additive Solutions and more.

New 3D printing partnerships from Carbon, Adaptive3D and SWISSto12

Kicking off this week’s roundup is the news that 3D printer OEM Carbon is expanding its European presence through strategic sales partnerships with 3D printing service providers Selltek and Solid Print3D. Selltek will become Carbon’s first sales partner in Italy while Solid Print3D will become the company’s first UK sales partner.

Carbon is seeking to build upon its success in Europe and fulfill growing demand in the region by making its technology more widely accessible.

“Europe is a strategic market for Carbon,” said Ellen Kullman, President and CEO at Carbon. “We’ve identified customer demand for our 3D printing innovations that provide unique advantages over design and manufacturing processes currently available. Solid Print3D and Selltek are strategic partners that will support our go-to-market strategy while bringing a level of regional expertise to support customers on their journey to make better products in less time.”

Elsewhere, 3D printing resin supplier Adaptive3D has entered into a materials distribution agreement with digital light processing (DLP) system and material producer EnvisionTEC to pair the former’s ToughRubber photoresins with the latter’s Xtreme 8K DLP printers. The partnership is seeking to accelerate the adoption of 3D printing for functional end-use elastomeric parts within the consumer, industrial, electrical, medical, and transportation sectors.

The combination of EnvisonTEC’s Xtreme 8K machine and Adaptive3D’s photoelastomer resins aims to deliver tough, durable parts that exhibit robust thermomechanical properties and high surface quality, quickly and in volume.

Meanwhile, Swiss radio frequency (RF) component supplier SWISSto12 has formed a strategic alliance to enable CAES to bring 3D printing technology to its US customers. The alliance grants CAES exclusive license to SWISSto12’s patents, trade secrets, and product designs, and the two partners will work together with US customers on new designs to meet the requirements of future aerospace and defense missions.

“This alliance enables fully trusted next-generation RF solutions for our customers that require the highest level of security, including Department of Defense and classified applications,” said David Young, Chief Technology Officer at CAES. “Through the transfer of best-in-class technology to a US market leader, leading aerospace and defense primes will now be able to deploy this technology on key programs requiring RF, microwave and milimeter-wave innovation.”

3D printer news from nScrypt, Desktop Metal, PrintParts, and Automation Alley

Moving onto 3D printer news, and microdispensing equipment manufacturer nScrypt has delivered a Factory in a Tool 3D printing system to Ozark Integrated Circuits, a player in the extreme environments and rugged electronics marketplace. The new system is a 3Dn Tabletop outfitted with a SmartPump microdispensing tool head and surface mapping laser that Ozark will use to print metal pastes for high temperature electronics applications.

“We expect our nScrypt Factory in a Tool to be a game changer for packaging integrated circuits for use in harsh environments, especially high temperature environments, which is our core expertise,” said Dr. A. Matt Francis, CEO and Founder of Ozark. “We plan to use the nScrypt system to develop processes and to fabricate our XNode rugged computer modules. We use the nScrypt Factory in a Tool to develop manufacturing techniques so that our XNodes, which can withstand temperatures up to 800⁰C, can be fabricated with lower cost and faster turnaround than with traditional manufacturing.”

Elsewhere, metal specialist Wall Colmonoy has installed the first Desktop Metal Shop System in the UK, and is now able to offer affordable and fast metal 3D printing of small to medium parts. With the new system installed, Wall Colmonoy will use it to produce innovative new parts for its atomization plant in Wales and to quickly implement tooling improvements that will reduce the downtime associated with waiting for replacement parts.

“This latest purchase marks a new chapter for Wall Colmonoy and we are inspired by the possibilities of metal 3D printing to really expand what we can make,” said Chris Weirman, Technical Director. “It’s exciting to be able to offer this route for customers who have smaller volumes or have parts that are difficult to cast.”

In other news, 3D printing service provider PrintParts has tripled its carbon fiber part production capacity, expanding its fleet of Markforged machines by 20 printers. PrintParts uses Markforged’s systems to produce end-parts for defense, industrial and medical applications using engineering-grade materials such as carbon fiber-filled nylon and Kevlar. The new systems will enable PrintParts to produce over 10,000 parts per week and shorten lead times for its customers.

Michigan’s Industry 4.0 knowledge center, Automation Alley, has hit its first milestone goal with its Project DIAMOnD initiative, having distributed 300 3D printers to small and medium-sized manufacturers in Oakland and Macomb County. Project DIAMOnD is an initiative to create the US’ largest 3D printer network on a blockchain technology platform.

“Automation Alley shepherded this funding to maximize its value to the state’s pandemic response and to advance our mission to accelerate the digital transformation of Michigan’s small and medium-sized manufacturers,” said CEO Tom Kelly.

“We again thank Oakland and Macomb Counties for their support and salute all of the area manufacturers who stepped up to participate in Project DIAMOnD and elevate Michigan’s 4.0 readiness and lessen the country’s dependence on foreign products while being prepared to help fight this pandemic.”

Business updates from ADDMAN Engineering Group and Intech Additive Solutions

Additive manufacturing service provider ADDMAN Engineering Group has acquired 3rd Dimension Industrial 3D Printing, an Indiana-based metal 3D printing service bureau. ADDMAN will add 3rd Dimension’s metal printing capabilities to its operation, including its Florida-based facility that produces a wide range of materials including nickel-based alloys, aluminum, high strength steels, and other materials currently in development.

3rd Dimension has previously printed parts for high-profile aerospace, racing and consumer goods industries for both prototyping and production applications.

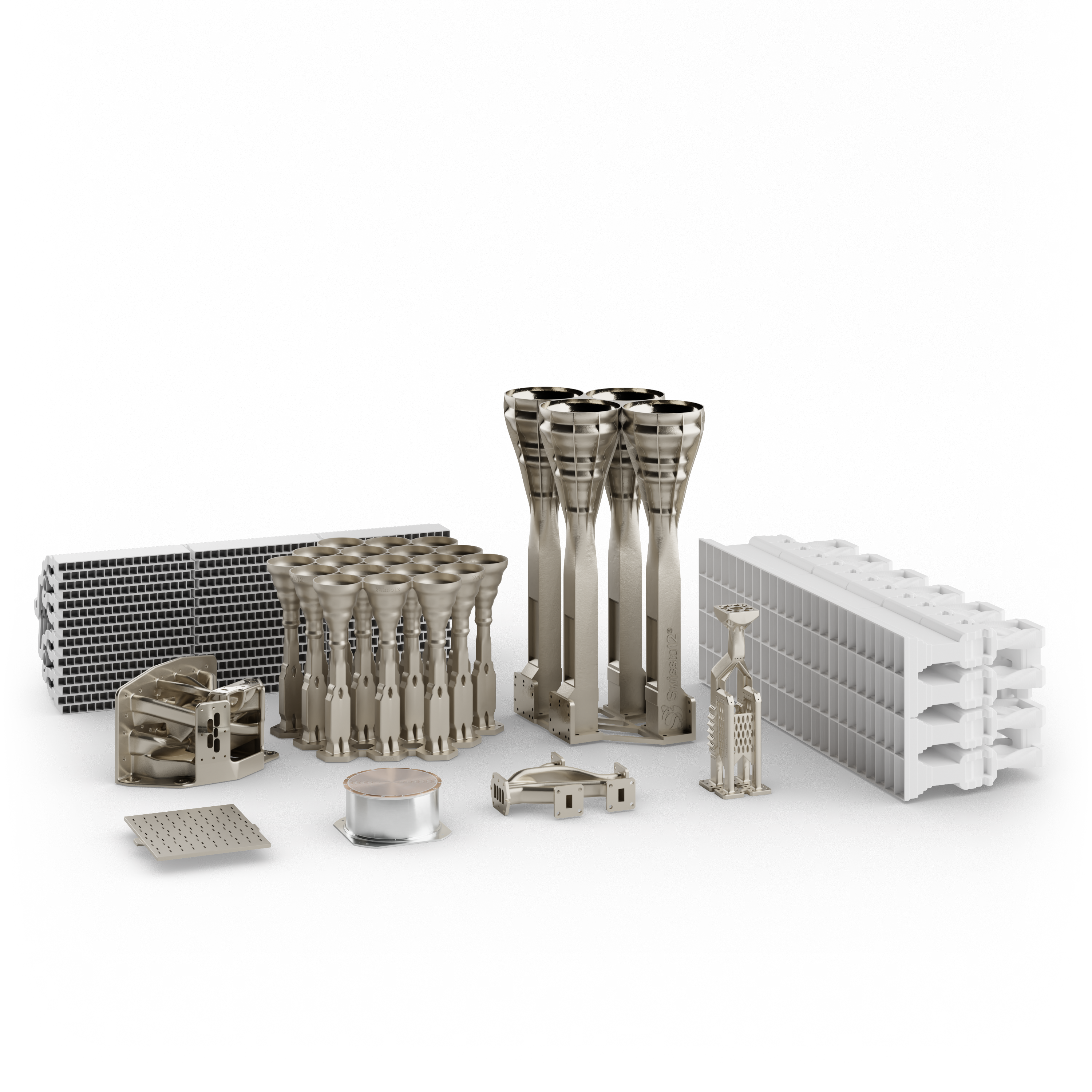

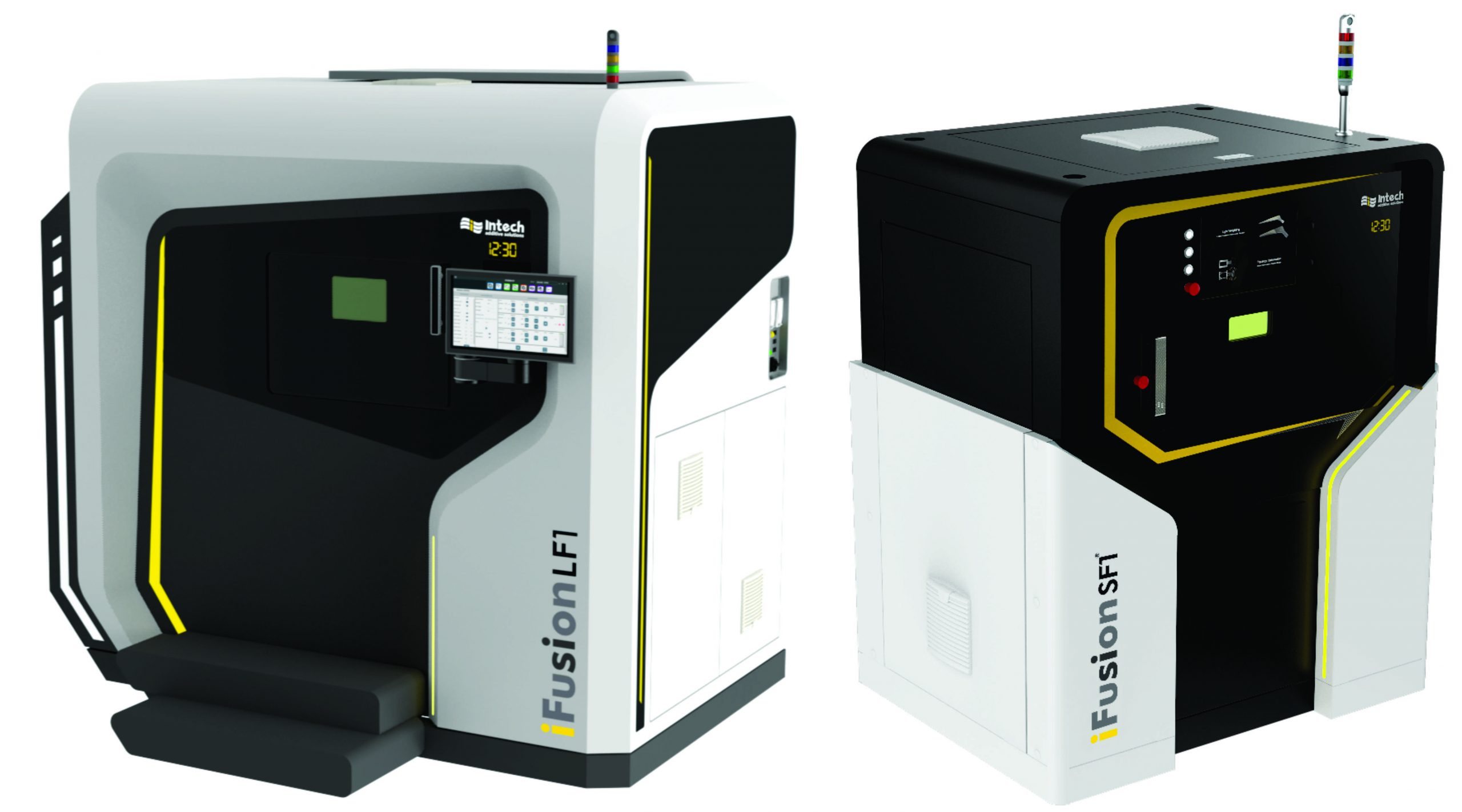

Bangalore-based 3D printer OEM Intech Additive Solutions has announced it bagged orders worth $2 million in FY 2020 for its ‘Made in India’ metal 3D printing systems. The company is claiming to be the first Indian OEM to “indigenously” develop, manufacture, and sell its iFusion series of metal 3D printers, alongside its AMBuilder build processing software and AMOptoMet parameter optimization software, against “stiff competition from global majors”. The company sold a total of six iFusion systems over the course of the year and is seeking to establish itself as a global OEM going forwards.

“We have focused on a steady and sustainable growth path despite the challenges of Covid and eforced lockdowns,” said Sridhar Balaram, Intech CEO. “It is exciting to see that our home grown iFusion series Metal AM systems, AM software suite AMBuilder and AMOptoMet has been well accepted and garnering increasing acclaim day by day as a better alternative to extremely expensive imported AM systems.”

Constellium secures ISO certification for AHEADD Aluminum powder

Dutch aluminum company Constellium has secured ISO certifications on quality management, environmental management, and occupational health and safety for the supply of its AHEADD aluminum alloy powders. The powders are specifically designed for the laser powder bed fusion (LPBF) 3D printing process to produce a range of applications within aerospace, automotive, and defense.

Constellium’s AHEADD powder alloys reportedly deliver productivity, residual stress, and geometric control benefits over aluminum silicon alloys, while providing components with advantageous strength, ductility, thermal, and electrical conductivity properties. According to the company, AHEADD powders have “unmatched” thermal stability and are capable of replacing titanium in selected applications to achieve weight and cost savings.

TÜV SÜD becomes WEF platform partner

Global certification firm TÜV SÜD has joined the World Economic Forum (WEF) as a platform partner covering areas within advanced manufacturing and production. The firm will focus on four initiatives – CO2 reduction in production, additive manufacturing, Smart Industry Readiness Index, and smart safety in connected manufacturing – and will contribute to discussions with experts in science, politics, and business regarding current “future-facing” issues.

TÜV SÜD will also work with the WEF to fast-track the industrialization of additive manufacturing in light of the technology’s ability to plug supply chain gaps during the Covid pandemic. The firm will draw up a position statement with ten leading manufacturers to raise awareness of the necessary changes among policy makers and within the business world to facilitate this.

3D printing material developments

In the first of several new material developments this week, Pennsylvania-based supplier of tooling and industrial materials Kennametal has launched the first Stellite powder qualified for laser powder bed (LPB) 3D printing. Stellite 21 AM is the latest addition to Kennametal’s portfolio of high-performance metal powders optimized for LPB 3D printing, and can be utilized for the production of high-performance wear components for the oil and gas and power generation industries.

Featuring a cobalt chrome molybdenum alloy matrix, the powder enables customers to achieve similar wear and corrosion resistance properties in 3D printed parts to those manufactured conventionally. It is suited to flow control applications and can be integrated into complex designs to mitigate cavitation, erosion, or corrosion failures.

In more news from Carbon, the company has unveiled the latest addition to its engineering-grade materials portfolio, EPU 41 Black. The company’s EPU 41 has been previously deployed for consumer applications such as the Adidas 4D midsole and fizik adaptive bike saddle, and is designed for the production-scale end-use elastomeric parts.

EPU 41 Black offers several improvements over its predecessor, EPU 41 Green, including greater local accuracy, faster print speeds, and a more neutral aesthetic, while providing the same mechanical properties. The material is particularly suited to applications that require energy return or cushioning, and is ideal for the 3D printing of highly-resilient elastomeric lattices. Leading sports brands Adidas, Specialized, and fizik have reportedly already leveraged EPU 41 Black’s benefits to develop next-generation products.

Spain-based 3D printing materials producer Recreus has added a new filament to its Filaflex range, the Filaflex 60A PRO, which it claims is the “most elastic” on the market. The material is designed for professional flexible printing, and is capable of returning to its original shape after stretching without deforming, as long as the elastic limit of the material is not exceeded.

Elsewhere, Polish 3D printer manufacturer Sinterit has launched a new polypropylene (PP) material for compact selective laser sintering (SLS) 3D printers. Based on a chemical-resistant that has low water absorption, the low-density material is reportedly unique in the SLS 3D printer segment that enables buoyant parts.

According to Sinterit’s co-founder and Chief Business Development Officer, the new PP is suitable for functional prototyping of the ducting in air intake, fan shrouds, and electronic housings, and will enable faster prototyping and short series production of final products. The material is able to withstand the pressurization of normal pneumatic systems and can be used to 3D print custom adapters, junctions, and sensor housings.

Rounding off this week’s 3D printing materials development is the release of new opaque color materials by 3D printer manufacturer Stratasys for its PolyJet 3D printers. The new VeroUltra materials are designed to simulate natural materials such as woods, fabrics, and marble, for high-quality opaque plastic parts in order to improve the realism of prototyping projects.

The opaque colors enable greater realism and graphic sharpness for prototyping applications such as bottle labels, mobile devices, back-lit screens and panels, and dolls. The VeroUltra materials are now available for Stratasys’ J8 Series and J7 Series 3D printers, and will extend to the J55 in June. Albuquerque-based 3D printed model designer, Dennis Harroun, has tested the new VeroUltra colors to create an art piece called “Gravity Girl”.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Albuquerque designer Dennis Harroun’s “Gravity Girl” model with the Sliced logo.