High-Quality Aluminum Busbars for Reliable Power Distribution are integral components within power distribution systems, designed to efficiently conduct electricity across different points. A busbar, typically made from aluminum or aluminum alloys, acts as a central hub in electrical systems, ensuring the reliable transmission of power while minimizing energy losses. The choice of aluminum for these bus bars is driven by its excellent conductivity, lightweight nature, and resistance to corrosion, making it a preferred material for both industrial applications and renewable energy systems. By utilizing High-Quality Aluminum Busbars for Reliable Power Distribution, industries can enhance the overall efficiency and safety of their power distribution infrastructure.

High-Quality Aluminum Busbars for Reliable Power Distribution | Definition and Functionality

Contents

- 0.1 High-Quality Aluminum Busbars for Reliable Power Distribution | Definition and Functionality

- 0.2 Advantages of Aluminum Over Other Materials

- 1 Characteristics of High-Quality Aluminum Busbars

- 2 Applications of Aluminum Busbars

- 3 Manufacturing Processes for Aluminum Busbars

- 4 Installation Considerations for Aluminum Busbars

- 5 Maintenance and Longevity of Aluminum Busbars

- 6 Conclusion

- 7 FAQS

- 7.1 What role does the aluminum bus bar play in enhancing the efficiency of modern power distribution systems?

- 7.2 How do aluminum bus bars contribute to various energy distribution applications in power generation and distribution systems?

- 7.3 How does the size reference of aluminum busbars influence their performance in various energy distribution systems?

- 7.4 Why is aluminum bus bar frequently used in power generation and distribution systems?

- 7.5 What are the advantages of using aluminum busbars in modern electrical installations?

- 7.6 Why is aluminum bus bar a popular choice in the design of electrical distribution systems?

High-Quality Aluminum Busbars for Reliable Power Distribution serve as essential components in electrical distribution systems. These busbars are typically made from extruded aluminum, which ensures superior conductivity and lightweight characteristics, making them ideal for transporting electrical loads efficiently. They play a critical role in connecting various electrical panels and systems, thereby ensuring a consistent power supply across numerous applications, including heavy machinery and electric vehicles. Quality control during manufacturing is crucial to maintain the integrity and longevity of these busbars, ensuring they can handle substantial power transmission without failure.

The functionality of High-Quality Aluminum Busbars for Reliable Power Distribution extends into diverse sectors, such as renewable energy systems and battery storage solutions. These busbars facilitate the connection between different parts of electrical power systems, optimizing energy flow in transportation and industrial settings. Their robust design accommodates varying electrical loads, which is vital for maintaining performance under fluctuating demands. By effectively managing electrical distribution, these busbars contribute to the overall efficiency and reliability of power supply, ensuring the smooth operation of modern technological applications.

| Busbar Type | Material | Current Rating (A) | Applications |

|---|---|---|---|

| Standard Aluminum Busbar | Aluminum | 1000 | Industrial Equipment, Electrical Panels |

| High-Conductivity Busbar | Aluminum Alloy | 2000 | Renewable Energy Systems, Substations |

| Flexible Aluminum Busbar | Aluminum | 800 | Electric Vehicles, Robotics |

| Insulated Aluminum Busbar | Aluminum with Insulation | 1500 | Battery Storage Solutions, Solar Power Systems |

Advantages of Aluminum Over Other Materials

High-Quality Aluminum Busbars for Reliable Power Distribution offer significant advantages compared to other metals like stainless steel. Aluminum is lightweight, which makes installation easier, especially in complex electrical systems such as distribution boards and battery packs. Its excellent conductivity allows for effective transfer of electrical power while minimizing energy losses. This attribute is particularly beneficial in renewable energy systems where efficiency is paramount for optimal performance.

Another notable benefit of aluminum is its corrosion resistance, which enhances the longevity of electrical equipment used in various settings. Unlike heavier metals, aluminum busbars remain stable under different environmental conditions and maintain their reliability over time. These properties make high-quality aluminum an ideal choice for various applications, including rail systems and industrial electrical distribution, ensuring a consistent and safe flow of electricity across all electrical systems.

Characteristics of High-Quality Aluminum Busbars

High-quality aluminum busbars for reliable power distribution are essential components in electrical systems, designed for optimal efficiency and durability. These busbars, often made from specific aluminum alloys, ensure effective energy transmission while minimizing resistance losses. The choice of insulation material is critical, as it enhances safety and performance by preventing corrosion and electrical failures. High-grade aluminum busbars are typically characterized by their robust construction, which not only supports superior conductivity but also withstands environmental challenges. Investing in electrical-grade aluminum busbars ensures long-term reliability and performance in various applications, from industrial power distribution to renewable energy systems.

Key Features to Look For

Choosing the right aluminum busbar is crucial for ensuring optimal performance in power distribution systems. High-Quality Aluminum Busbars for Reliable Power Distribution come in various forms, including insulated aluminum busbars and aluminum busbar systems. Analyzing aluminum busbar options allows for tailored solutions that meet specific aluminum busbar needs. Understanding aluminum busbar grades is vital, as different aluminum busbars exhibit varying conductivity, strength, and resistance to corrosion, impacting their overall efficiency.

Seeking top-quality aluminum busbars involves assessing their key features, including material purity and thickness. Insulated aluminum busbars offer safety and reliability, making them ideal for high-voltage applications. The right aluminum busbar can significantly improve system performance while minimizing energy losses. By focusing on aluminum grade busbars with superior characteristics, users can enhance the durability and longevity of their electrical infrastructure, ensuring High-Quality Aluminum Busbars for Reliable Power Distribution.

- Ensure material purity for optimal conductivity

- Check thickness specifications to meet application needs

- Look for insulated options for enhanced safety

- Evaluate corrosion resistance to prolong lifespan

- Assess mechanical strength for durability under load

- Consider customization options for specific requirements

- Research suppliers for reputation and quality assurance

Importance of Material Purity

Material purity is crucial for the performance and reliability of aluminum busbars. High-Quality Aluminum Busbars for Reliable Power Distribution must adhere to stringent aluminum busbar specifications to ensure optimal conductivity and mechanical strength. Conductive aluminum busbars crafted from top-grade aluminum alloys reduce energy losses and enhance efficiency in power distribution systems. The integrity of these materials, whether for standard or custom aluminum busbars, directly impacts their functionality and longevity.

Insulation and purity levels also affect the safety and effectiveness of aluminum bus bars. Insulated aluminum bus bars, designed for specific applications, require high purity to prevent electrical failures. Custom-shaped aluminum busbars and various aluminum busbar designs serve unique industrial needs. Ensuring that aluminum busbars are made from pure materials not only enhances performance but also plays a vital role in maintaining safety standards in modern power distribution systems.

Applications of Aluminum Busbars

High-Quality Aluminum Busbars for Reliable Power Distribution play a pivotal role in various applications, particularly within industrial settings. These busbars, often available as insulated aluminum bus options, provide an efficient conduit for electrical currents, making them a preferred choice over traditional copper busbar options. Industries can choose aluminum bus products for their lightweight nature and corrosion resistance, enhancing overall system longevity. The use of aluminum bus pipe in renewable energy systems exemplifies its versatility, allowing for seamless integration with solar and wind power infrastructures. To ensure optimal functionality, it is crucial to consider busbar thickness and incorporate aluminum bus designs that meet specific electrical requirements, thereby maximizing performance and safety.

Power Distribution in Industrial Settings

In industrial settings, the importance of High-Quality Aluminum Busbars for Reliable Power Distribution cannot be overstated. These busbars provide a reliable aluminum metal option, ensuring efficient energy transmission across various applications. Available in different busbar sizes, these systems can be tailored to fit specific operational requirements. Unlike copper bus bars, high-quality aluminum alloy busbars offer a lightweight yet robust alternative. Such characteristics make them particularly favorable for compact bus bar installations, where space efficiency is essential.

Choosing the right busbar type is crucial for optimal performance in industrial environments. Combination busbars play a vital role in reducing installation complexity and enhancing system flexibility. The busbar surface quality contributes significantly to conductivity and heat dissipation, ensuring longevity and performance. Flexible busbars are ideal for systems that require adaptability to changing layouts. With careful selection of chosen busbars, facilities can leverage the benefits of high-quality aluminum busbars for reliable power distribution, promoting safety and efficiency in electrical setups.

Use in Renewable Energy Systems

The integration of High-Quality Aluminum Busbars for Reliable Power Distribution plays a crucial role in renewable energy systems such as solar and wind power. These busbars provide effective solutions for high-current power distribution, ensuring that energy generated from renewable sources is efficiently transferred. Various styles, including flat bus bars and round bus bars, are available to accommodate specific needs. Adhering to electrical-grade aluminum standards guarantees reliability and longevity in these demanding applications.

Choosing aluminum options such as insulated bus bars and galvanized busbars is essential for enhancing safety and performance. Proper bus bar size and configuration can significantly impact the overall efficiency of renewable energy systems. An insulated aluminum guide can assist in selecting the right type for specific installations, promoting reliable power distribution while minimizing energy loss. High-Quality Aluminum Busbars for Reliable Power Distribution ultimately serve as a backbone for sustainable energy solutions.

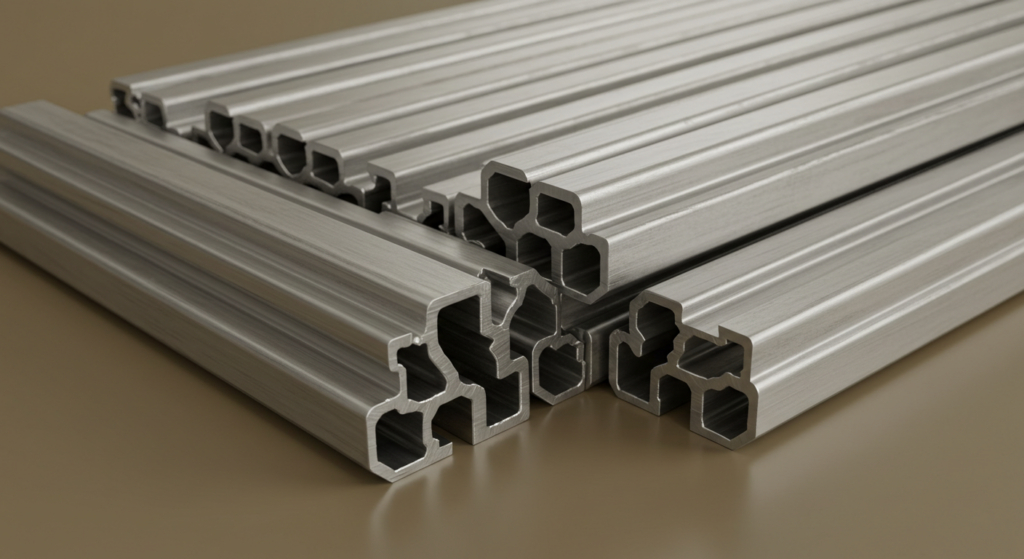

Manufacturing Processes for Aluminum Busbars

High-Quality Aluminum Busbars for Reliable Power Distribution are crafted through precise manufacturing processes that ensure their functionality and efficiency. Superior bus bars are manufactured using appropriate grade aluminum, with electrical-grade aluminum being a popular choice for optimal conductivity and strength. The process typically involves extrusion techniques that create various bus bar options tailored for specific bus bar applications. Each bus bar size reference is crucial for meeting diverse power distribution needs, particularly in commercial power distribution setups. By utilizing high-quality materials and stringent quality control measures, manufacturers ensure that these bus bar systems deliver efficient power distribution, making them essential for both industrial and renewable energy projects.

Extrusion Techniques

Extrusion techniques play a crucial role in the production of high-quality aluminum busbars for reliable power distribution. This process involves forcing heated aluminum through a die to create bus bars that meet specific dimensions and shapes tailored to various power distribution requirements. The use of electrical grade aluminum ensures the resulting bus bar products have excellent conductivity. By utilizing specific aluminum alloys, manufacturers can enhance performance, making these bus bars reliable for large-scale power distribution systems.

High-quality aluminum busbars offer superior advantages over traditional copper bus bars, particularly in weight and cost-effectiveness. Efficient extrusion not only shapes the bus bars but also optimizes busbar trunking conductors for seamless integration into electrical systems. It is essential to maintain precise bus bar dimensions to ensure compatibility and safety in complex electrical setups. As a result, this technique contributes significantly to creating aluminum products that meet the demands of reliable energy distribution across various applications.

- Enhanced electrical conductivity due to the use of electrical grade aluminum

- Lightweight compared to traditional copper options

- Cost-effective alternative for power distribution systems

- Customizable dimensions and shapes to meet specific needs

- Improved performance with specialized aluminum alloys

- Seamless integration into existing electrical infrastructures

- Ensures safety and compatibility in complex layouts

Quality Control Measures

Ensuring the integrity of High-Quality Aluminum Busbars for Reliable Power Distribution begins with rigorous quality control measures throughout the manufacturing process. Every step, from selecting the right aluminum grade to the detailed examination of aluminum alloy properties, is crucial for producing flexible bus bars suited for high-voltage power distribution. By implementing strict testing protocols, manufacturers can verify the performance of aluminum material used in main distribution panels, ensuring it meets the standards required for optimal function in industrial power distribution.

Bus packaging plays a significant role in maintaining the quality of the product during transit and storage. Each batch of High-Quality Aluminum Busbars for Reliable Power Distribution is carefully packaged to protect against damage and deterioration. Properly identifying the exact aluminum grade and utilizing top-grade aluminum alloys allows for consistent performance across power distribution systems. By adhering to these quality control measures, manufacturers can deliver reliable solutions that cater to the specific demands of various applications.

Installation Considerations for Aluminum Busbars

Ensuring the successful installation of High-Quality Aluminum Busbars for Reliable Power Distribution involves a keen understanding of various factors. The use of aluminum pipes and round rods is essential in creating a robust power distribution network that can handle significant power loads. Proper setup techniques are vital for achieving reliable power transmission, particularly in modern power distribution systems, which often include long-span bus applications and rail power supply setups. It is crucial to implement best practices that promote stable power distribution and address potential challenges, ensuring the longevity and efficiency of aluminum busbars in power distribution projects. By prioritizing comprehensive conductive aluminum elements, operators can effectively support high-power systems, enhancing overall performance and reliability.

Best Practices for Safe Setup

Ensuring a safe setup of High-Quality Aluminum Busbars for Reliable Power Distribution involves careful planning and the use of appropriate components. The integration of aluminum coils and seamless bus pipes enhances the system’s overall efficiency, allowing for reliable distribution across various industrial power setups. Attention to detail is necessary, particularly when aligning busbars to achieve optimal performance and minimize resistance. Proper connections with battery connectors play a crucial role in maintaining the reliability of the distribution system, especially in high-efficiency applications like battery storage facilities.

Installation should always consider the unique demands of different power systems. The choice of high-quality materials is vital to support efficient power transmission. Prioritize safety and compliance with industry standards to prevent mishaps during setup. Regular inspections and maintenance will help identify potential issues that may arise, ensuring the longevity and reliability of the busbars. By implementing these practices, companies can maximize the benefits of High-Quality Aluminum Busbars for Reliable Power Distribution in their operations.

Common Challenges and Solutions

High-Quality Aluminum Busbars for Reliable Power Distribution can face several challenges during installation and operation. In power systems, issues such as thermal expansion and contraction can affect their performance, particularly in environments where heavy machinery operations are prevalent. Ensuring that busbars are adequately insulated and secured is essential, especially in transportation facilities where they are subjected to vibration and movement. The proper integration of aluminum busbars into energy distribution systems must consider the unique requirements of battery systems, which demand robust connections to maintain efficiency.

Addressing these challenges involves implementing effective solutions tailored to specific applications. Regular inspections and maintenance are crucial to identify wear and tear in any power distribution setup. For high-voltage equipment, meticulous attention to battery wiring is necessary to prevent failures. Designing aluminum busbars specifically for reliable energy distribution can significantly enhance their performance in transportation industry applications. By proactively managing these factors, operators can ensure the longevity and effectiveness of High-Quality Aluminum Busbars for Reliable Power Distribution.

Maintenance and Longevity of Aluminum Busbars

Proper maintenance is essential to ensure the longevity of High-Quality Aluminum Busbars for Reliable Power Distribution. Regular inspections help identify potential issues, especially in applications like wind power installations where weather conditions can impact performance. By utilizing aluminum sheets of top-tier quality, operators can enhance the overall system efficiency of electrical distribution systems. Meeting the electrical load demands of low-voltage equipment within electrical panels is crucial for maintaining reliable performance. For modern energy distribution and transportation product manufacturing, implementing routine checks and upkeep can significantly boost the unmatched reliability of aluminum busbars, ensuring they meet evolving electrical infrastructure needs.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Monthly | Check for physical damage, corrosion, or signs of wear. |

| Electrical Testing | Quarterly | Measure electrical resistance and ensure connections are secure. |

| Thermal Imaging | Annually | Identify hot spots and abnormal temperature variations in busbar connections. |

| Cleaning | Bi-Annually | Remove dust and debris to prevent overheating and improve conductivity. |

Conclusion

High-Quality Aluminum Busbars for Reliable Power Distribution play a crucial role in ensuring efficient and dependable power transmission across various applications. Their lightweight nature, combined with excellent conductivity, makes them an optimal choice for industries seeking durability and reliability. As organizations increasingly prioritize energy efficiency and sustainability, the implementation of High-Quality Aluminum Busbars for Reliable Power Distribution will only grow in significance. Such busbars not only enhance operational performance but also contribute to reducing overall energy costs, making them indispensable in modern power systems.

FAQS

What role does the aluminum bus bar play in enhancing the efficiency of modern power distribution systems?

The aluminum bus bar plays a vital role in modern power distribution systems due to its high efficiency and ability to conduct electricity within a power distribution network. Aluminum busbars are crafted from top-grade aluminum alloys, which offer superior conductivity compared to copper busbars and stainless steel busbars. This contributes to an efficient energy distribution, ensuring reliable performance in various power generation and distribution systems. Additionally, the aluminum offers benefits like lightweight construction and cost-effectiveness, making it an ideal choice for enhancing distribution system efficiency.

How do aluminum bus bars contribute to various energy distribution applications in power generation and distribution systems?

Aluminum bus bars play a vital role in modern power distribution systems as they are designed to conduct electricity within a power distribution network. They are frequently used in power generation and distribution systems due to their efficient conductivity and lightweight properties. The busbars offer various sizes, making them suitable for different applications, and detailed aluminum alloy specifications ensure optimal performance. Additionally, the aluminum round rod is often utilized to create busbars, highlighting their importance in reliable power distribution.

How does the size reference of aluminum busbars influence their performance in various energy distribution systems?

The busbar size reference is crucial because it dictates the current-carrying capacity and overall efficiency of the system. Aluminum can be an excellent choice for busbars offers optimal performance in various energy distribution applications. When properly sized, aluminum busbars are frequently used in power generation and distribution systems due to their lightweight, conductivity, and cost-effectiveness.

Why is aluminum bus bar frequently used in power generation and distribution systems?

Aluminum bus bars are frequently used in power generation and distribution systems due to their lightweight nature, excellent conductivity, and corrosion resistance, which makes them ideal for reliable power distribution in various applications.

What are the advantages of using aluminum busbars in modern electrical installations?

Aluminum busbars are frequently used in power generation and distribution systems due to their excellent conductivity, lightweight properties, and cost-effectiveness. These advantages make them an optimal choice for various electrical applications, enhancing overall system performance and reliability.

Why is aluminum bus bar a popular choice in the design of electrical distribution systems?

Aluminum bus bar is frequently used in power generation and distribution systems due to its cost-effectiveness, lightweight properties, and good conductivity, making it an ideal solution for efficient electrical distribution.