Aluminum busbars serve as a crucial component in lightweight, efficient power distribution systems. These bus bars facilitate the conduction of electrical current, allowing for streamlined electrical power distribution across various applications. Aluminum’s natural lightweight composition makes it an ideal choice for busbars, especially in settings where reducing overall weight is critical, such as in overhead power lines. The conductivity of aluminum matches that of traditional copper solutions while offering significant advantages in terms of cost and corrosion resistance. As industries continue to seek innovative solutions for their power distribution needs, understanding the role of aluminum busbars becomes essential for optimizing performance and efficiency.

Aluminum Busbars | Lightweight, Efficient Power Distribution | Definition and Functionality

Contents

- 0.1 Aluminum Busbars | Lightweight, Efficient Power Distribution | Definition and Functionality

- 0.2 Advantages Over Traditional Copper Solutions

- 1 Characteristics of Aluminum Busbars

- 2 Efficient Power Distribution with Aluminum Busbars

- 3 Applications of Aluminum Busbars

- 4 Design Considerations for Aluminum Busbars

- 5 Installation and Maintenance of Aluminum Busbars

- 6 Conclusion

- 7 FAQS

- 7.1 What are the benefits of using aluminum bus bars in power distribution systems?

- 7.2 How do the properties of aluminum busbars differ from other materials used in electrical bus bars in high-efficiency power distribution systems?

- 7.3 What roles do aluminum bus bars play in enhancing the efficiency of power distribution systems?

- 7.4 How do aluminum bus bars contribute to reducing energy loss in power distribution systems?

- 7.5 What is the elevated role of aluminum in modern power distribution systems?

- 7.6 What is the elevated role of aluminum in contemporary power distribution strategies?

- 7.7 In what ways does the elevated role aluminum influence the design of modern power distribution systems?

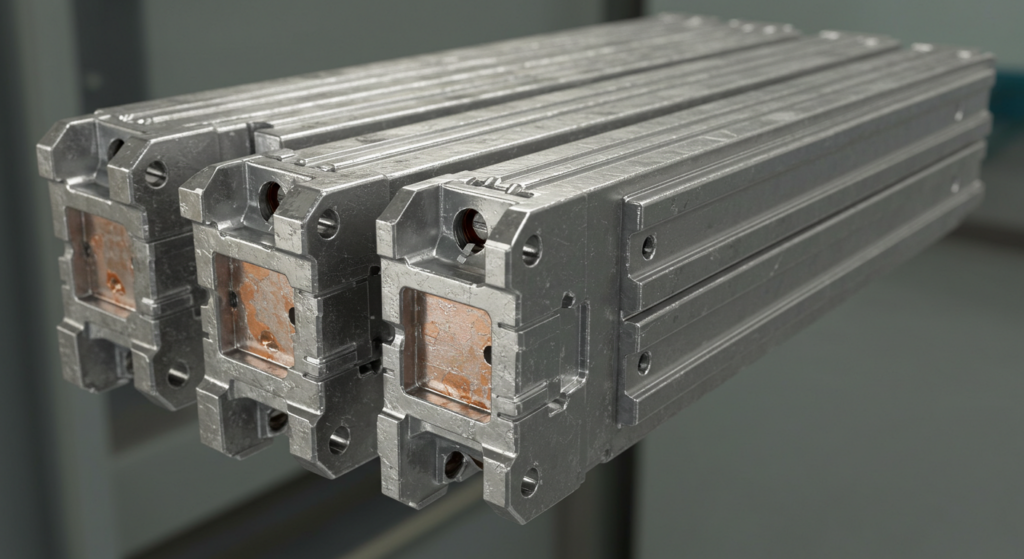

Aluminum busbars serve as crucial components in electric power systems, facilitating the efficient distribution of electricity. Their lightweight composition and high conductivity make them an ideal choice for use in bus ducts and busways. Made from aluminum alloys, these busbars are easier to handle than traditional copper solutions, which helps streamline installation processes, especially in environments with heavy machinery. The use of aluminum allows for significant energy savings and contributes to overall system efficiency.

The functionality of aluminum busbars extends beyond just weight and conductivity. They play an essential role in electrical distribution networks, aiding in the effective management of power flow within various industrial and commercial settings. The benefits of aluminum recycling also come into play, as aluminum extraction processes continue to evolve, making aluminum alloys more sustainable and cost-effective. Resources such as aluminum.org highlight the advantages of incorporating these materials into modern electricity distribution systems, emphasizing their role in promoting energy efficiency and reliability.

Advantages Over Traditional Copper Solutions

Aluminum Busbars | Lightweight, Efficient Power Distribution serve as an innovative alternative to traditional copper solutions. Their lightweight composition allows for easier handling and installation, which is especially advantageous in distribution boards and other confined spaces. The lower weight of aluminum, compared to copper, reduces the overall structural load on buildings and infrastructures. This is critical for electric distribution systems, where maintaining optimal power flow and efficiency is essential. Aluminum’s ability to handle high electric power demands makes it a reliable option in modern applications, including electric vehicles (EVs) and energy storage systems.

Cost-effectiveness is another significant benefit of aluminum busbars over copper. The more abundant availability of aluminum contributes to lower material costs, making them an attractive option for manufacturers and engineers. Aluminum has excellent thermal conductivity and resistance to corrosion, promoting long-term energy efficiency in power transmission applications. Enhanced performance in electric vehicles and the utilization of aluminum in energy-efficient technologies underscore its role in advancing sustainable practices. Overall, the advantages of aluminum busbars position them as a superior choice in contemporary electric distribution solutions.

Characteristics of Aluminum Busbars

Aluminum Busbars play a crucial role in modern electrical systems, offering lightweight and efficient power distribution essential for various applications. Their lightweight composition makes them ideal for use in battery storage systems and power inverters, allowing for reduced overall weight without compromising structural integrity. This characteristic proves beneficial in transportation, where minimizing weight can lead to lower energy consumption. Furthermore, Aluminum Busbars efficiently conduct electricity, making them suitable for connecting electrical panels, machines, and solar power systems. This efficient power distribution not only enhances performance but also contributes to energy-efficient designs that align with contemporary sustainability goals.

Lightweight Composition

The lightweight composition of aluminum busbars makes them an ideal solution for various applications, particularly in renewable energy systems and wind power installations. Their reduced weight facilitates easier handling and installation, which is crucial in portable electronics and vehicles. By minimizing the structural load on support systems, aluminum busbars enhance the overall efficiency of power distribution networks. Their lightweight nature is essential for the transmission of electricity over long distances, making them a preferred choice in utility operations.

Aluminum busbars contribute to higher efficiency levels in power systems due to their favorable strength-to-weight ratio. High-quality aluminum busbars are designed to withstand demanding environments while maintaining their lightweight properties. This characteristic not only supports efficient power distribution but also ensures longevity and reliability in various settings. The combination of lightweight and durability positions aluminum busbars as an essential element in modern electrical infrastructure.

Corrosion Resistance

Aluminum busbars exhibit excellent corrosion resistance, making them ideal for various electrical applications. The lightweight and durable nature of these aluminum bus bars ensures longevity and dependability in even the harshest environments. High-quality aluminum bus bars can withstand exposure to moisture and chemicals without compromising performance. This corrosion resistance allows for consistent power delivery as they maintain their conductivity over time, ensuring that advanced aluminum busbars are suitable for modern electrical systems.

State-of-the-art aluminum busbars contribute significantly to efficient power distribution by minimizing energy losses due to corrosion. The resistance to rust and degradation means that aluminum busbars will function effectively and safely throughout their lifespan. By choosing reliable aluminum bus bars for installations, companies can enhance their electrical systems while ensuring lower maintenance costs and increased operational efficiency. These benefits underscore the vital role aluminum bus bars play in achieving lightweight, efficient power distribution across various sectors.

Efficient Power Distribution with Aluminum Busbars

Aluminum busbars play a crucial role in achieving lightweight, efficient power distribution within electrical systems. These advanced busbars utilize high-quality busbar materials that facilitate optimal current flow while minimizing weight. The choice to incorporate aluminum bus instead of traditional copper busbars offers significant benefits, such as reduced thermal expansion and enhanced corrosion resistance. With their ability to accommodate long busbar lengths, aluminum solutions allow for flexible installation in various configurations. High-quality busbar products ensure reliability and performance in demanding conditions, making aluminum an increasingly popular choice in modern busbar systems. Selecting the right busbar material is essential for maintaining energy efficiency and system effectiveness.

Role in Electrical Systems

Aluminum busbars serve a crucial role in electrical systems through their lightweight and efficient power distribution capabilities. These customized busbars provide an effective alternative to traditional copper bus bars, ensuring that power distribution panels operate with high efficiency. By utilizing aluminum connectors, these systems can achieve a balance between reduced weight and robust performance. The use of bus bar fasteners further enhances the stability and reliability of connections, facilitating seamless integration into electrical infrastructure for upcoming or next busbar projects.

The implementation of insulated bus bars in electrical systems significantly improves safety and efficiency. Thicker bus bars made from aluminum can handle greater current loads while minimizing energy losses. The strategic design of aluminum busbars allows for optimized layouts, enabling efficient power distribution throughout various applications. This efficiency not only meets the demands of modern electrical installations but also reduces operational costs, making aluminum a preferred choice in cutting-edge electrical projects.

Impact on Energy Efficiency

Aluminum Busbars | Lightweight, Efficient Power Distribution plays a crucial role in enhancing energy efficiency within electrical systems. These lightweight and durable components facilitate high-current power distribution while minimizing resistive losses. The use of high-quality aluminum as a bus bar material allows for effective heat dissipation, reducing the risk of overheating in large-scale power distribution setups. This efficient design not only meets the power distribution needs of modern infrastructure but also contributes to significant energy savings over time.

The adoption of aluminum bus bars enables operators to streamline their electrical layouts, leading to reduced installation costs and improved overall reliability. With the right bus bar connectors, the seamless integration of aluminum bars ensures optimal performance in various applications. This efficient power distribution method is particularly beneficial in industrial and commercial settings, where high-current demands are prevalent. The lightweight nature of aluminum also allows for easier handling and installation, further supporting energy-efficient operations in complex electrical systems.

Applications of Aluminum Busbars

Aluminum Busbars deliver lightweight, efficient power distribution across various applications, making them ideal for both industrial and commercial settings. Their high-strength aluminum composition enhances power distribution capabilities while maintaining a lower weight compared to copper bus systems. This lightweight nature allows for easier installation and adaptability in different configurations, such as rhi busbars designed specifically for high-demand scenarios. The flexibility in bus bar dimensions enables tailored solutions for unique power distribution systems, ensuring optimal performance. By integrating aluminum busbars into commercial power distribution, facilities can benefit from reduced energy losses and improved efficiency, solidifying their position as a preferred choice in modern electrical infrastructure.

Industrial Settings

Aluminum Busbars | Lightweight, Efficient Power Distribution are increasingly essential in industrial settings due to their remarkable capability to handle high-power applications. Unlike traditional materials, aluminum achieves an optimal power efficiency while maintaining a lightweight design, making it ideal for modern power distribution systems. Their effective integration into power distribution networks ensures reliable power distribution, addressing the demands of evolving industrial operations.

The versatility of aluminum busbars allows for seamless incorporation into various industrial applications, enhancing overall power distribution efforts. This adaptation not only supports established power distribution networks but also facilitates the design of new, more efficient configurations. As industries continue to prioritize sustainability and efficiency, aluminum’s inherent properties provide a significant advantage over conventional copper solutions, positioning it as a key component in the future of reliable power distribution.

Commercial Installations

Aluminum Busbars | Lightweight, Efficient Power Distribution play a vital role in commercial installations by serving as reliable bus solutions. These components facilitate efficient power systems, ensuring optimal performance in main distribution panels. With their lightweight characteristics, aluminum busbars can be easily integrated into bus duct products, allowing for customizable bus duct designs that cater to specific energy demands. Their elevated role in managing power distribution makes them an ideal choice for businesses requiring dependable and efficient energy solutions.

Utility-scale power systems benefit significantly from the use of aluminum materials in their infrastructure. Custom aluminum busbars can be tailored to meet unique installation requirements, reinforcing the efficiency of busway systems. By choosing the correct bus bar configurations for commercial applications, companies can optimize their energy distribution, minimize downtime, and improve overall operational efficiency. The versatility of aluminum busbars positions them as essential components in the modern commercial electrical landscape.

Design Considerations for Aluminum Busbars

Designing Aluminum Busbars requires careful consideration of various factors to ensure optimal performance in energy distribution. The use of high-quality aluminum alloy enhances the lightweight, efficient power distribution characteristics of these busbars, making them ideal for high-power applications. Proper sizing and configuration are critical to support heavy machinery operations and compact installations, as well as to facilitate efficient distribution in power systems. Effective thermal management is also essential, as aluminum conducts electricity well and can generate heat under high loads. Balancing these design elements can lead to superior energy efficiency and seamless integration into bus duct solutions, ensuring that Aluminum Busbars provide reliable and efficient power management.

Size and Configuration

Aluminum Busbars are designed to conduct electricity within a power distribution network while maintaining high load conditions. The size and configuration of these busbars are crucial for ensuring consistent power flow in high-efficiency systems. Properly engineered aluminum materials enhance their functionality, making them a preferred choice for various applications, including automotive power solutions and wind power installations. The lightweight nature of aluminum allows for simpler handling and installation without compromising on performance.

Selecting the appropriate size and configuration of aluminum busbars can significantly influence the overall efficiency of power networks. Their adeptness at managing high load conditions directly impacts superior energy efficiency in lightweight, efficient power distribution systems. As aluminum fabrication delivers bespoke solutions tailored to specific requirements, it ensures that these busbars not only perform reliably but also contribute to long-term sustainability in energy use across different industries.

Thermal Management

Effective thermal management is crucial for maximizing the performance of Aluminum Busbars | Lightweight, Efficient Power Distribution. The use of high-grade aluminum alloy ensures that these busbars can efficiently dissipate heat generated during large-scale power transmission. Proper design and configuration help maintain optimal operating temperatures, which in turn enhances overall system efficiency. In lightweight applications, such as battery storage systems, effective thermal management also reduces transportation costs by minimizing the need for additional cooling mechanisms.

Aluminum forms such as busbars play a significant role in energy-efficient systems through power monitoring. Implementing the right thermal management strategies allows for better heat distribution, preventing hotspots that can adversely affect power employs. The aluminum fabrication process can be tailored to include features that promote efficient thermal flow, ensuring that the busbars maintain their integrity and functionality over time. Ultimately, a well-managed thermal environment contributes to the longevity and reliability of aluminum busbars in various applications.

Installation and Maintenance of Aluminum Busbars

Proper installation and maintenance of aluminum busbars are crucial for ensuring their performance in electrical infrastructures. These lightweight solutions provide efficient power distribution in various applications, including industrial control panels and battery connections. Attention to detail during installation promotes seamless power flow, enhancing electric efficiency and cost-efficiency in high-load scenarios. Regular maintenance practices contribute to the overall reliability of aluminum busbars, ensuring they operate at optimal efficiency and continue to meet the demands of modern power usage. Implementing these best practices helps maintain the longevity and effectiveness of aluminum busbars in diverse electrical systems.

Best Practices for Installation

Proper installation of aluminum busbars is essential for achieving optimal performance in lightweight, efficient power distribution systems. It is important to ensure that the busbars are sized and configured according to specific power requirements. This includes taking into account the current capacity needed for various applications, such as renewable energy installations or electrical control panels. A well-planned arrangement aids in minimizing voltage drops and maintaining stability across electrical infrastructure, including panels and electrical systems.

Attention to detail during installation can significantly impact overall energy consumption and the effectiveness of energy-efficient grids. Adequate thermal management must be considered to prevent overheating, facilitating the safe transport of power through aluminum busbars. This careful installation process not only enhances performance but also ensures that the electrical panels operate optimally under varying load conditions, thereby contributing to efficient and reliable power distribution.

Routine Maintenance Tips

Regular inspections are crucial for maintaining Aluminum Busbars, especially in high-current applications. Checking for signs of corrosion or wear can help ensure optimal performance. Keeping the busbars free from dust and debris promotes reliable distribution and assists in meeting energy efficiency goals. Pay special attention to connections and terminations, as any loose fittings can lead to increased resistance, affecting load handling and current loads.

Cleaning the busbars should be performed using appropriate methods to avoid damaging the lightweight surface. An effective approach involves utilizing non-conductive cleaning agents that can remove contaminants without compromising the integrity of the system. For renewable energy installations, monitoring the busbars’ performance over time helps to ensure that they continue to support efficient power distribution, particularly in systems that integrate high-voltage equipment. Regular maintenance extends the lifespan of Aluminum Busbars, promoting reliable operation in various applications.

Conclusion

Aluminum busbars play a crucial role in modern electrical systems, offering lightweight and efficient power distribution for a variety of applications. Their design allows for effective handling of both mechanical and electrical loads, making them suitable for integration in automation equipment. The advantages of aluminum busbars over traditional copper solutions enhance energy efficiency while ensuring durability and performance across various loads. As industries continue to evolve, the demand for aluminum busbars remains strong, highlighting their significant contribution to reliable and efficient electrical infrastructure.

FAQS

What are the benefits of using aluminum bus bars in power distribution systems?

Aluminum bus bars play a vital role in modern power distribution systems due to their high energy efficiency and lightweight nature. High-quality aluminum offers superior conductivity and mechanical strength, making aluminum busbar suitable for various applications. Additionally, aluminium materials differ from traditional copper options by providing excellent performance under mechanical loads while ensuring cost-effectiveness. When selecting top-quality aluminum bus for your needs, consider the high-quality busbar options available in the market for optimal performance.

How do the properties of aluminum busbars differ from other materials used in electrical bus bars in high-efficiency power distribution systems?

Aluminum busbars play an elevated role in high-efficiency power distribution due to their lightweight nature and excellent electrical conductivity. The aluminum ensures minimal energy losses and facilitates the use of new energy aluminum setups. Unlike copper, aluminum busbars can be easily machined, which allows for more flexibility and customization in design. This differentiation makes them an ideal choice for modern electrical busbars in various applications.

What roles do aluminum bus bars play in enhancing the efficiency of power distribution systems?

Aluminum bus bars play an elevated role in enhancing the efficiency of power distribution systems due to their lightweight nature, excellent electrical conductivity, and durability. Compared to other materials, aluminum differ in terms of cost-effectiveness and performance, making them an ideal choice for modern electrical applications.

How do aluminum bus bars contribute to reducing energy loss in power distribution systems?

Aluminium bus bars play an elevated role in minimizing energy loss during electrical transmission. Their lightweight nature and excellent conductivity allow for more efficient power distribution, ultimately leading to lower operational costs and improved overall system performance.

What is the elevated role of aluminum in modern power distribution systems?

The elevated role of aluminum in modern power distribution systems is significant due to its lightweight nature and excellent conductivity. Aluminum busbars provide a reliable solution for efficient power distribution, minimizing energy loss while ensuring structural integrity in various applications.

What is the elevated role of aluminum in contemporary power distribution strategies?

The elevated role of aluminum in contemporary power distribution strategies is significant due to its lightweight nature, excellent conductivity, and cost-effectiveness. These attributes make aluminum an ideal choice for efficient power distribution, as it helps in minimizing energy loss while ensuring reliable performance in various electrical systems.

In what ways does the elevated role aluminum influence the design of modern power distribution systems?

The elevated role aluminum plays in modern power distribution systems is crucial for enhancing efficiency and reducing overall weight. Its excellent conductivity, corrosion resistance, and cost-effectiveness make aluminum a preferred choice for electrical components, allowing for more streamlined and effective power distribution strategies.